SCR-H series/ SCR-3224H / SCR-4224H / SCR-5224H / SCR-6224H /

CNC Double Column CROSSRAIL Machining Center

| Item / Model | Unit | SCR-3224H | SCR-4224H | SCR-5224H | SCR-6224H |

|---|---|---|---|---|---|

| X-Axis Travel | mm | 3200 | 4200 | 5200 | 6200 |

| Y-Axis Travel | mm | 2400 | |||

| Z-Axis Travel | mm | 760 ( 1000 ) | |||

| W-Axis Travel | mm | 1400 | |||

| Table Size | mm | 3000 x 2200 | 4000 x 2200 | 5000 x 2200 | 6000 x 2200 |

| T-Slots Dimension | mm | 22 ( 24、28 ) | |||

| Table Load Capacity | kgs | 10000 | 15000 | 17500 | 25000 |

| Distance between Twe Columns | mm | 2500 | |||

| Distance from Spindle Nose to Table | mm | 0 ~ 1800 | |||

| Spindle Taper, Tool Shank | ISO NO.50(40) BT-50、CAT-50、DIN 69871、HSK-A100 | ||||

| Spindle Speed Range | rpm | 20 ~ 4000 ( 30 ~ 6000 ) ( 80 ~ 8000 ) ( 100 ~ 10000 ) | |||

| Main Motor Output (30 min Rating/Cont) |

HP | 30 / 25 ( 35 / 30 ) | |||

| Rapid Traverse Rate X,Y Axis | mm/min | 10000 ( 12000 ) | |||

| Rapid Traverse Rate Z Axis | mm/min | 12000 ( 15000 ) | |||

| Cutting Feed Rate | mm/min | 1 ~ 5000 ( 1 ~ 8000 ) | |||

| Minimum Input Increment | mm/min | 0.001 | |||

| Tool Magazine Capacity | pcs | ( 20 / 32 / 40 / 60 / 80 ) | |||

| Max. Tool Diameter / Adjacent Pockets Empty |

mm | Ø125 / Ø 210 | |||

| Max. Tool Length (from Gauge Line) |

mm | 350 | |||

| Max. Tool Weight | kgs | (18 / 20) | |||

| Tool selection Method | (ABS, Random Bi) | ||||

| Tool Change Time(T-T)(approx) | secs | 11 ( 4.5 ) | |||

| Power Requirement | Kva | 60 | 75 | ||

| Floor Space Requirement | mm | 11200x7700 | 13200x7700 | 15200x7700 | 17500x7700 |

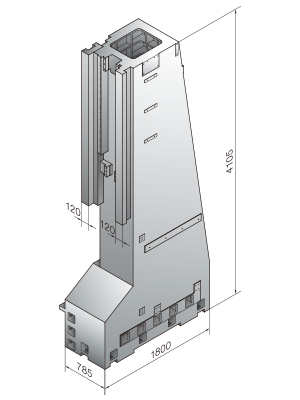

| Machine Height from Floor Level | mm | 5140 ( 5490 ) | |||

| Machine Weight(approx) | kgs | 40000 | 46000 | 63500 | 77500 |

| CNC Controller | Fanuc、Meldas、Siemens、Heidenhain series etc. |

||||

| Positioning Accuracry | mm | JIS B6338 0.01/300 , VDI 3441 P0.035 | |||

| Repeatability Accuracy | mm | ±0.005 | |||

Note:

- ( ) Description is optional accessories.

- To research and improve our company keep the right of changing design and structure at any time, this data is just for reference.

- LUBRICATION SYSTEM

- GLAZED WINDOW-TYPE SPLASH GUARD

- SCREW-TYPE CHIP CONVEYOR

- LINK-TYPE CHIP CONVEYOR

- COOLANT EQUIPMENT

- SPINDLE OIL COOLER

- Z-AXIS HYDRAULIC BALANCE UNIT

- PNEUMATIC UNIT

- AIR BLOW FOR CHIP ( BY M-CODE )

- WORK LAMP

- AUTO POWER-OFF

- M.P.G

- PROGRAM END&ALARM LAMP

- RS-232 INTERFACE

- LEVELING BLOCK AND BOLTS

- TOOL KIT

- MAINTENANCE AND OPERATION MANUAL

- CONTROLLER OPERATION MANUAL AND ELECTRICAL CIRCUIT DIAGRAM

- INSPECTION LIST

- AUXILIARY TABLE

- NC(ROTARY TABLE,INDEX TABLE)

- 20、32、40、60、80 ATC MAGAZINE CAPACITY

- TOOL PRESETTER

- AUTO TOOL LENGTH DIAMETER MEASUREMENT

- AUTO TOUCH PROBE SYSYTEM

- LINEAR SCALE FEEDBACK

- COOLANT THROUGH SPINDLE SYSTEM

- OIL HOLE TOOL SHANK DEVICE

- COOLANT AUTO AIR MIST DEVICE

- COOLANT NOZZLE ANGLE REMOTE CONTROL

- MANUAL 45° , 90° ANGLE HEAD、UNIVERSAL HEAD、EXTENSION HEAD; MANUAL SET-UP AUTO DEVIDED 5° POSITION (RIGHT ANGLE HEAD, SWING DEVIDED ANGLE HEAD, 45° ANGLE HEAD)

- SPINDLE THERMAL COMPENSATION

- AVALIABLE WITH DIFFERENT SPINDLE SPEC & RPM

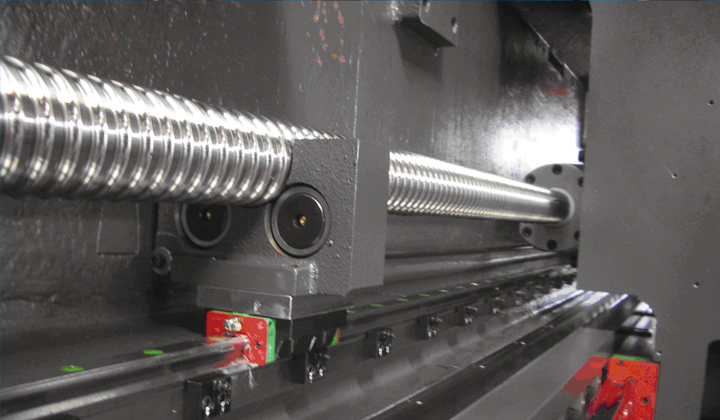

- SIGMA CNC Patent - The spindle ram and Z-axis are designed with 4-linear guideways (Roller type guideway, width 45mm) and a box-way construction. During heavy cutting vibrations are eliminated, and during fine cutting inert does not occur, resulting in higher surface accuracy.

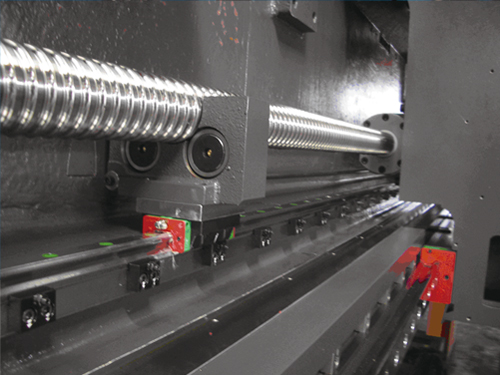

- All three axes(X, Y, Z) are Roller type linear guideways.

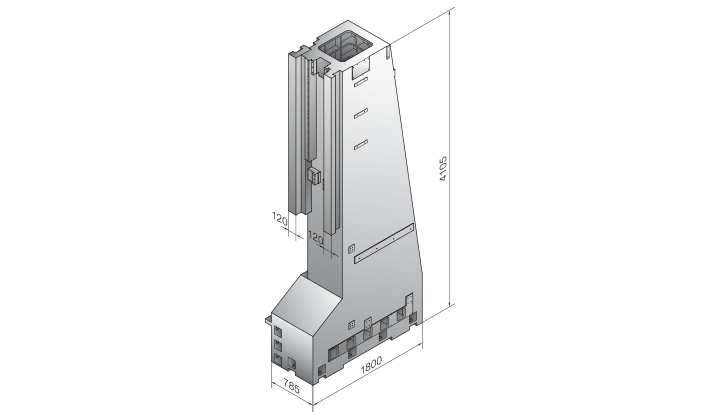

- Stronger W-axis (box-way) with Super Column Design

W-axis Standard Stroke 1400mm. (It is possible to be custom-made)

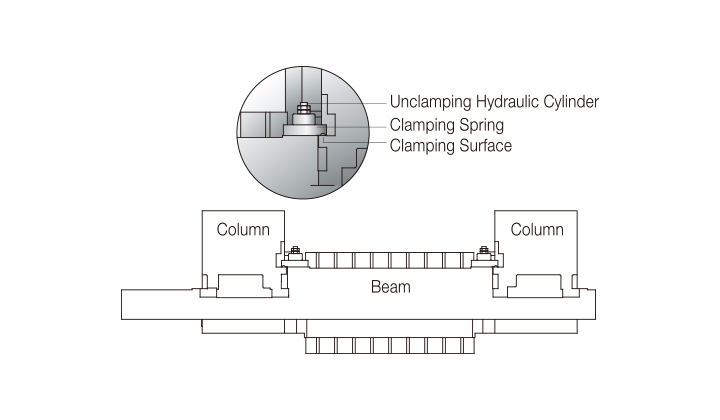

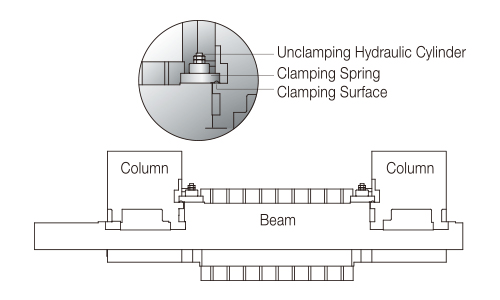

- Powerful Clamping Mechanism for W-axis

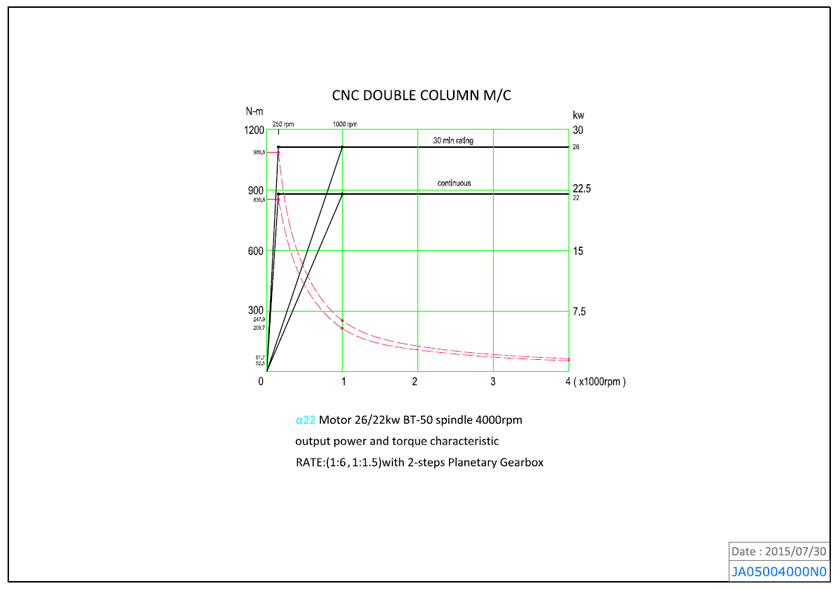

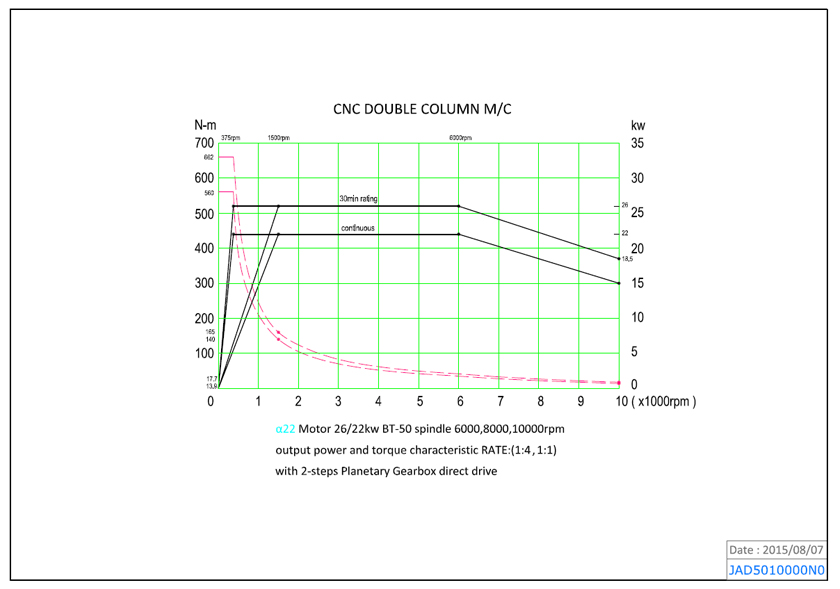

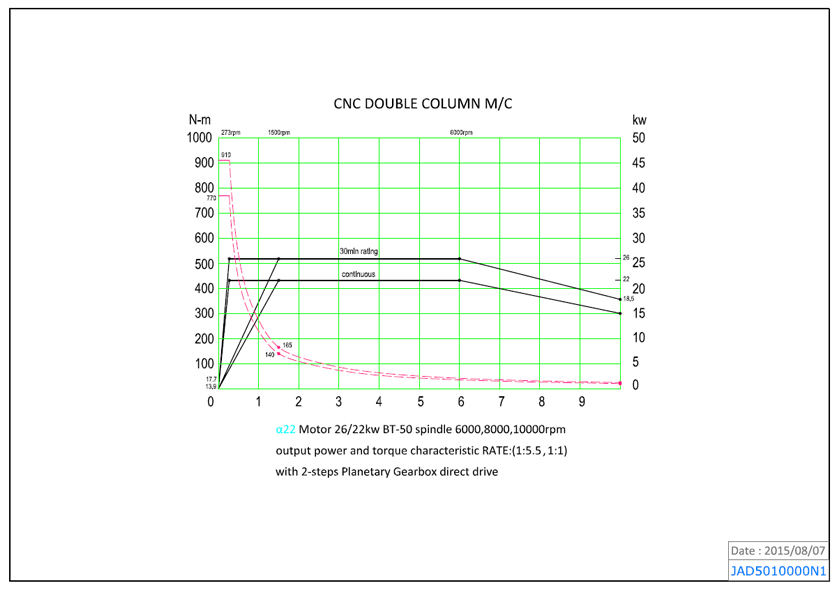

- Belt Drive Spindle

With 2-steps Planetary Gearbox

BT-50, Max. 4000rpm

- Direct-Drive Spindle with 2-steps Planetary Gearbox (Optional)

BT-50, 6000rpm / 8000rpm / 10000rpm

High Speed & High Torque in One Machine

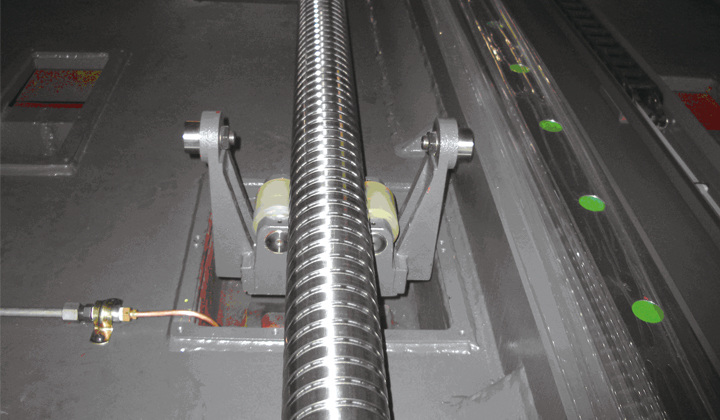

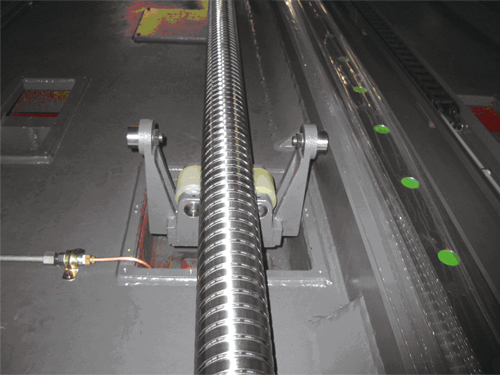

- Supporter for Ballscrew on X-axis

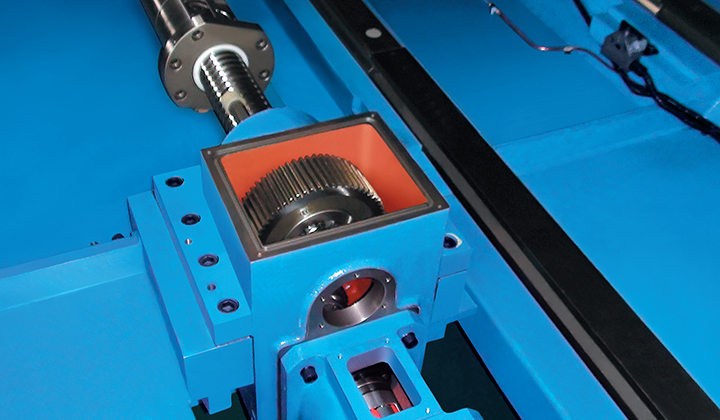

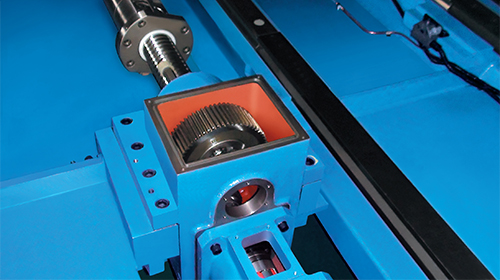

- X-axis Free Backlash Transmission Gearbox

- Supporter for Ballscrew on Y-axis

- Operator’s Box by Lift Mechanism special for large machinery only.