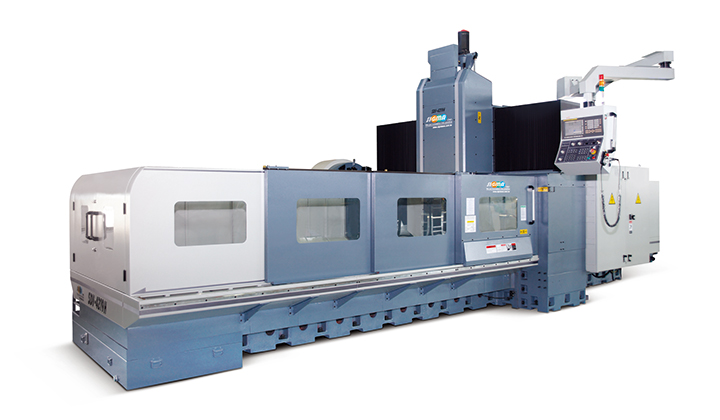

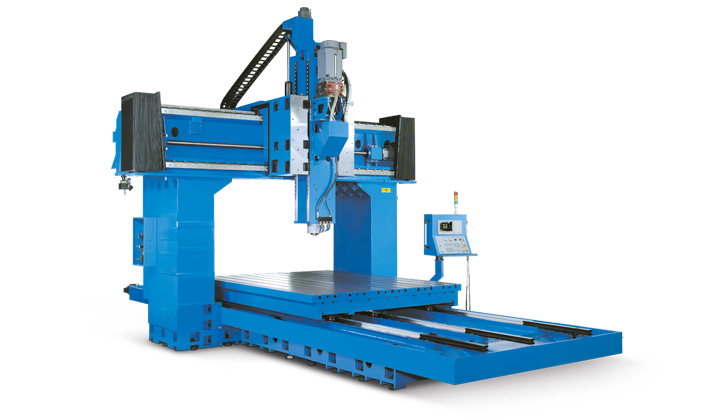

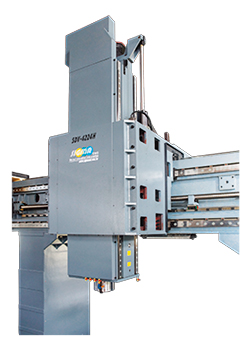

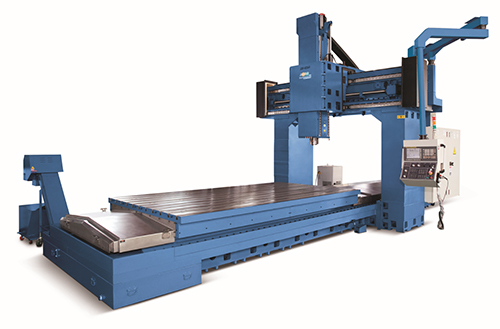

SDV-H series/ SDV-4239H / SDV-5239H / SDV-6239H /

CNC High Precision Double Column Machining Center

The CNC high-precision double column machining center is the best equipment for large-size workpiece machining. SIGMA offers various types of CNC high-precision double column machining centers to fit every machining requirement. These double-column machining centers are widely used in mold manufacturing, automotive industry, aerospace industry, electronics industry, machine tool manufacturing and etc. If you have an interest in other products, CNC Moving Column Horizontal Machining Center would be one of your choices!

| Item / Model | Unit | SDV-4239H | SDV-5239H | SDV-6239H |

|---|---|---|---|---|

| X-Axis Travel | mm | 4200 | 5200 | 6200 |

| Y-Axis Travel | mm | 3900 | ||

| Z-Axis Travel | mm | 760 ( 1000 )( 1200 )( 1400 ) | ||

| Table Size | mm | 4000 x 3700 | 5000 x 3700 | 6000 x 3700 |

| T-Slots Dimension | mm | 22 ( 24、28 ) | ||

| Table Load Capacity | kgs | 21000 | 25000 | 32500 |

| Distance between Twe Columns | mm | 4000 | ||

| Distance from Spindle Nose to Table | mm | 165 ~ 925 / 270 ~ 1030 165 ~ 1165 / 270 ~ 1270 165 ~ 1365 / 270 ~ 1470 165 ~ 1565 / 270 ~ 1670 |

||

| Spindle Taper, Tool Shank | ISO NO.50(40) BT-50、CAT-50、DIN 69871 (BT-40、CAT-40)、HSK-A63、HSK-A100 | |||

| Spindle Speed Range | rpm | 20 ~ 4000 ( 30 ~ 6000 ) ( 100 ~ 10000 ) ( 80 ~ 8000 ) ( 12000 ~ 24000 ) | ||

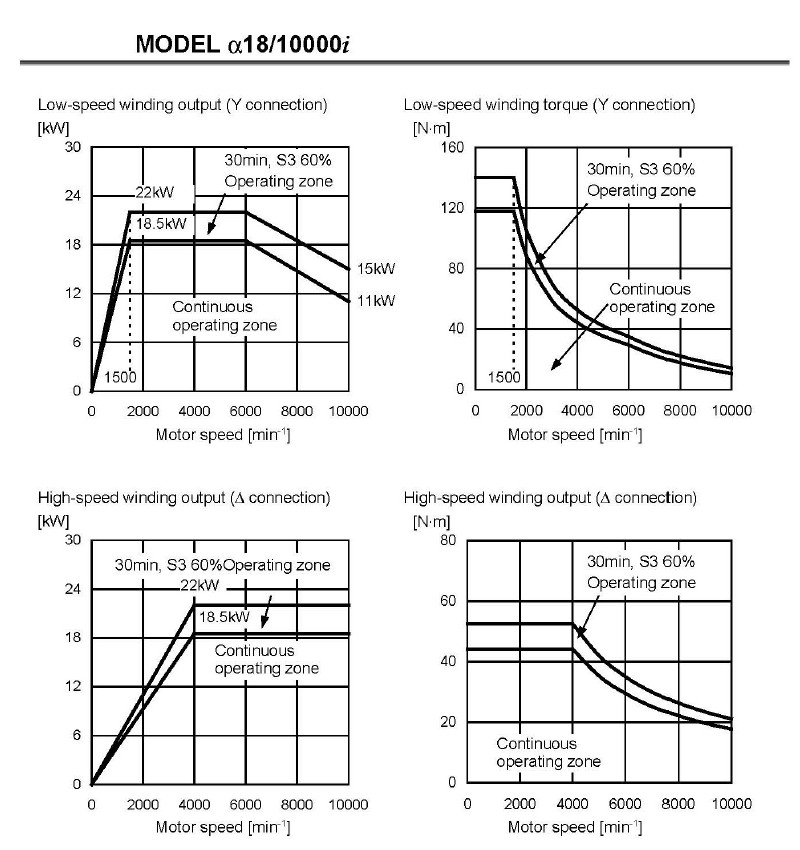

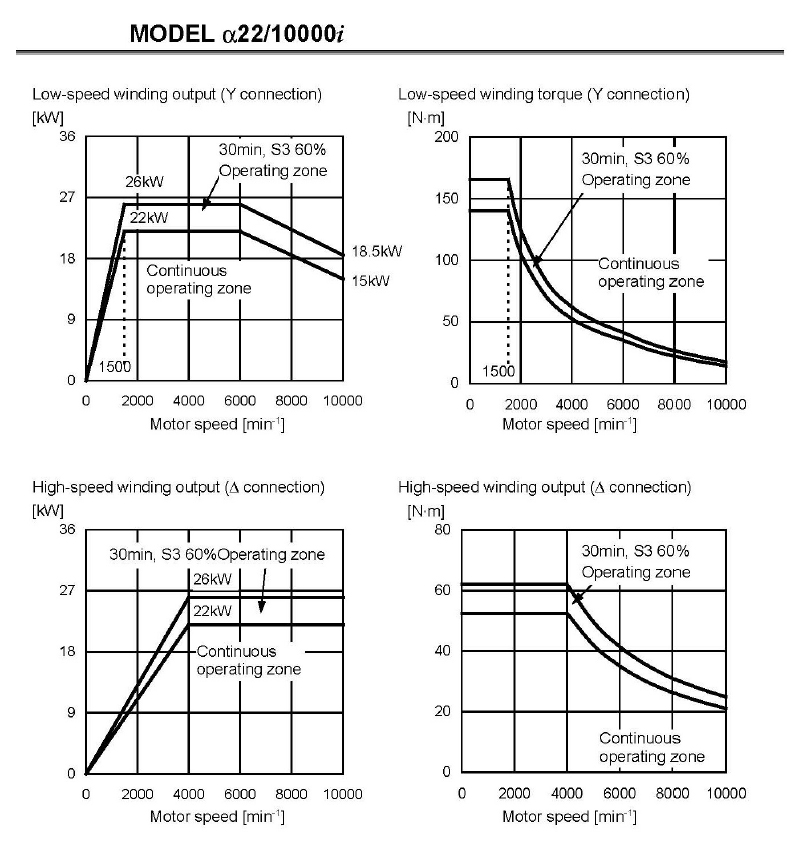

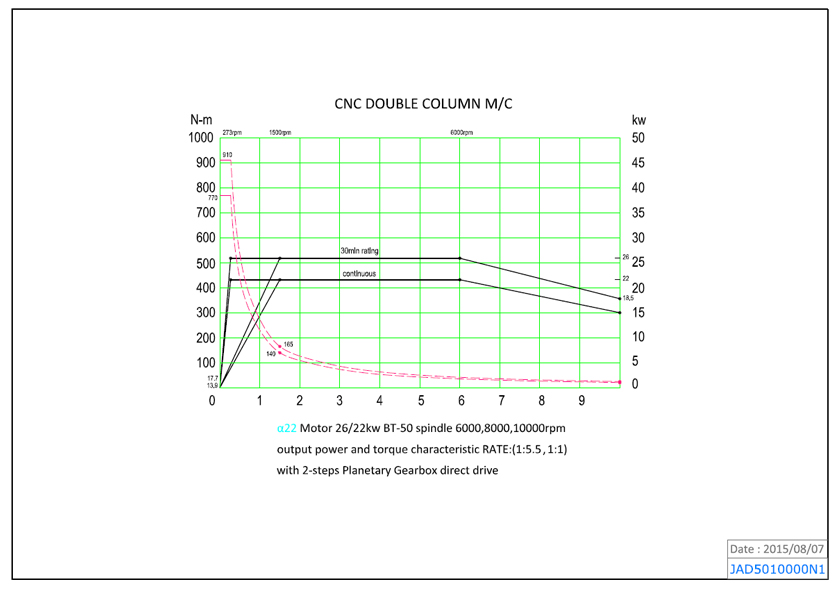

| Main Motor Output (30 min Rating/Cont) |

HP | 30 / 25 ( 35 / 30 ) | ||

| Rapid Traverse Rate X,Y Axis | mm/min | 10000 ( 12000 ) | ||

| Rapid Traverse Rate Z Axis | mm/min | 12000 ( 15000 ) | ||

| Cutting Feed Rate | mm/min | 1 ~ 5000 ( 1 ~ 8000 ) | ||

| Minimum Input Increment | mm/min | 0.001 | ||

| Tool Magazine Capacity | pcs | ( 20 / 32 / 40 / 60 ) | ||

| Max. Tool Diameter / Adjacent Pockets Empty |

mm | Ø125 / Ø 210 | ||

| Max. Tool Length (from Gauge Line) |

mm | 350 | ||

| Max. Tool Weight | kgs | (18 / 20) | ||

| Tool selection Method | ( ABS、Random Bi ) | |||

| Tool Change Time(T-T)(approx) | secs | 8 ( 4.5 ) | ||

| Power Requirement | Kva | 55 ( 60 ) | 60 ( 65 ) | |

| Floor Space Requirement | mm | 13000x8500 | 15000x8500 | 17300x8500 |

| Machine Height from Floor Level | mm | 4250 / 4830 / 5510 / 6110 | ||

| Machine Weight(approx) | kgs | 48500 | 67500 | 80500 |

| CNC Controller | Fanuc、Meldas、Siemens、Heidenhain series etc. |

|||

| Positioning Accuracry | mm | JIS B6338 0.01/300 , VDI 3441 P0.035 | ||

| Repeatability Accuracy | mm | ±0.005 | ||

Note:

- ( ) Description is optional accessories.

- To research and improve our company keep the right of changing design and structure at any time, this data is just for reference.

- LUBRICATION SYSTEM

- GLAZED WINDOW-TYPE SPLASH GUARD

- SCREW-TYPE CHIP CONVEYOR

- LINK-TYPE CHIP CONVEYOR

- COOLANT EQUIPMENT

- SPINDLE OIL COOLER

- Z-AXIS HYDRAULIC BALANCE UNIT

- PNEUMATIC UNIT

- AIR BLOW FOR CHIP ( BY M-CODE )

- WORK LAMP

- AUTO POWER-OFF

- M.P.G

- PROGRAM END&ALARM LAMP

- RS-232 INTERFACE

- LEVELING BLOCK AND BOLTS

- TOOL KIT

- MAINTENANCE AND OPERATION MANUAL

- CONTROLLER OPERATION MANUAL AND ELECTRICAL CIRCUIT DIAGRAM

- INSPECTION LIST

- AUXILIARY TABLE

- NC(ROTARY TABLE,INDEX TABLE)

- 20、32、40、60、ATC MAGAZINE CAPACITY

- TOOL PRESETTER

- AUTO TOOL LENGTH DIAMETER MEASUREMENT

- AUTO TOUCH PROBE SYSYTEM

- LINEAR SCALE FEEDBACK

- COOLANT THROUGH SPINDLE SYSTEM

- OIL HOLE TOOL SHANK DEVICE

- COOLANT AUTO AIR MIST DEVICE

- COOLANT NOZZLE ANGLE REMOTE CONTROL

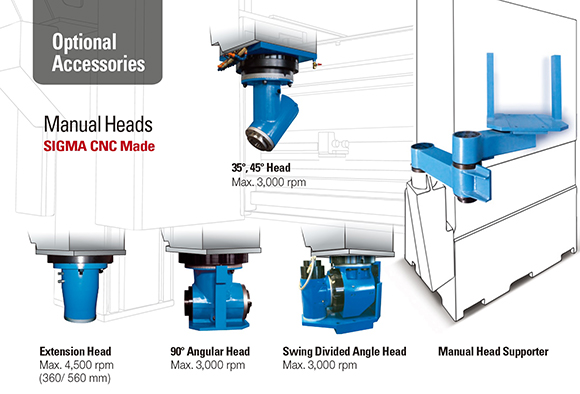

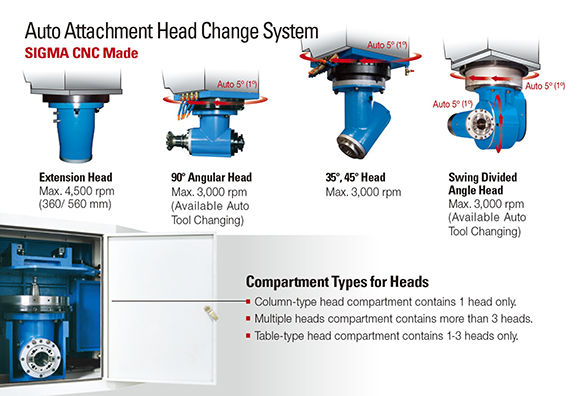

- MANUAL 45° , 90° ANGLE HEAD、UNIVERSAL HEAD、EXTENSION HEAD; MANUAL SET-UP AUTO DEVIDED 5° POSITION (RIGHT ANGLE HEAD, SWING DEVIDED ANGLE HEAD, 45° ANGLE HEAD)

- SPINDLE THERMAL COMPENSATION

- AVALIABLE WITH DIFFERENT SPINDLE SPEC & RPM

- MANUAL FULL SPLASH GUARD

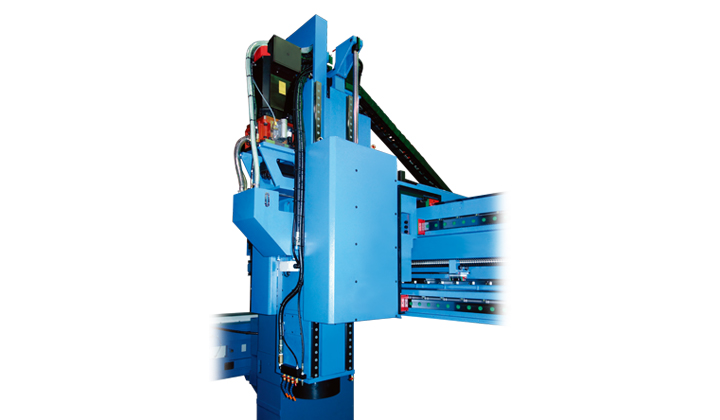

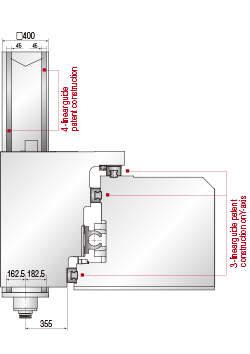

- SIGMA CNC Patent - The spindle ram and Z-axis are designed with 4-linear guideways (Roller type guideway, width 45mm) and a box-way construction. During heavy cutting vibrations are eliminated, and during fine cutting inert does not occur, resulting in higher surface accuracy.

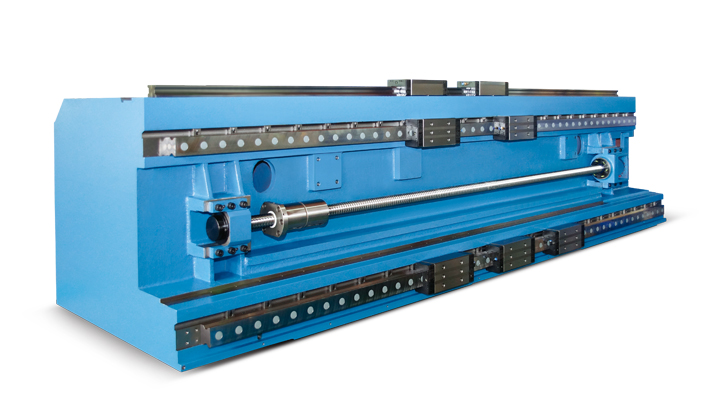

- SIGMA CNC Patent – Y-axis configured by 3-linear guideways (Roller type guideway, width 65mm) for horizontal and vertical directions that offer greater stability and rigidity for the machine.

- All three axes(X, Y, Z) are Roller type linear guideways.

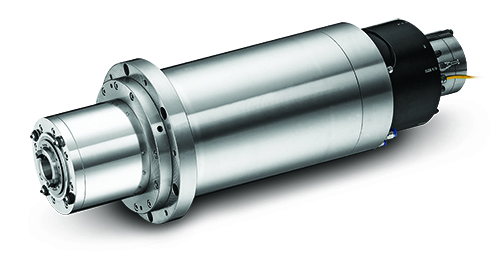

- Direct Drive Spindle (Optional)

(BT-50, 10000rpm)

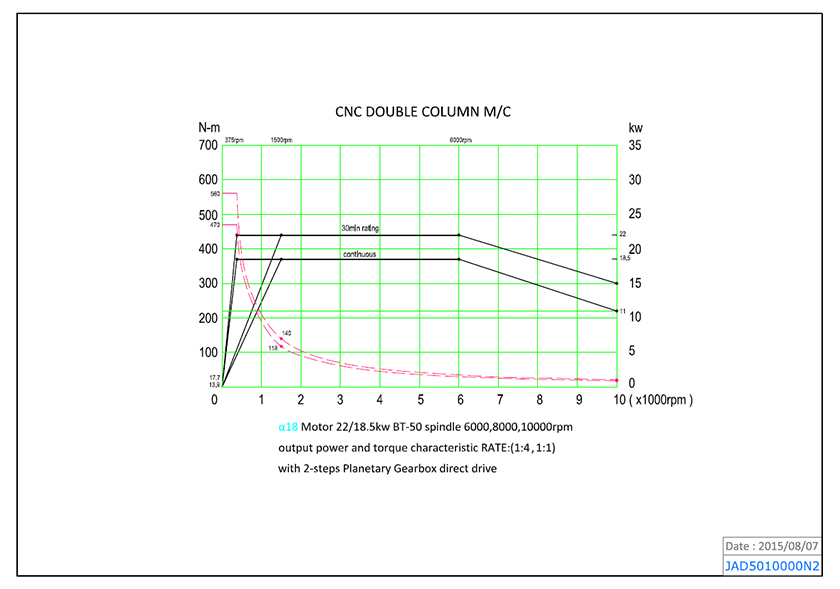

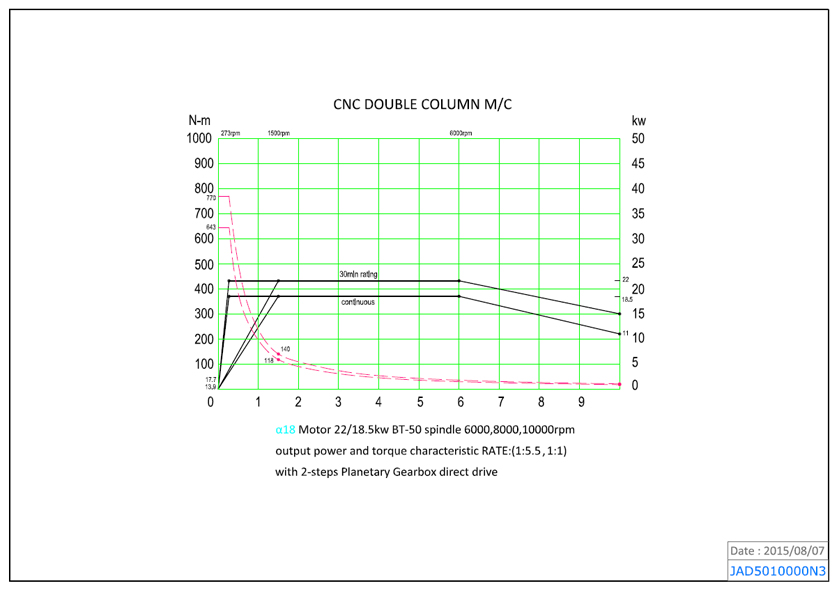

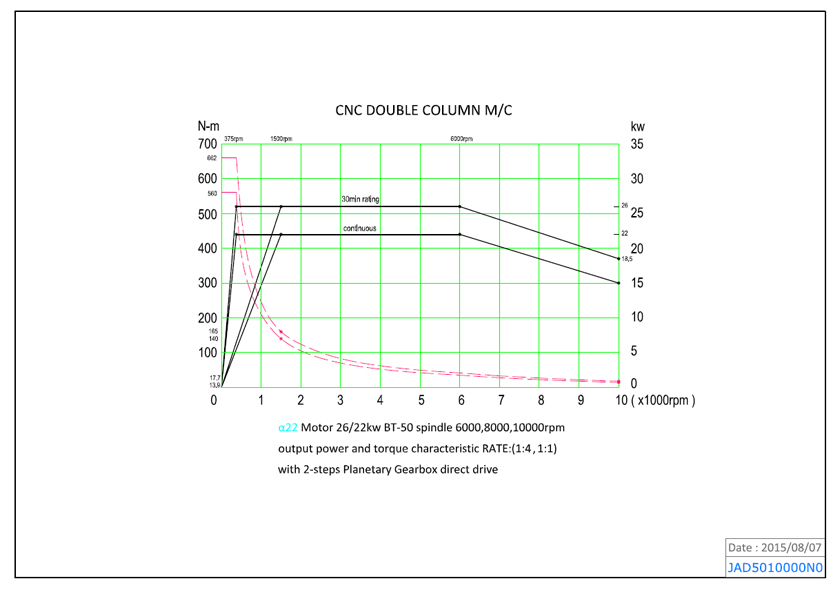

- Direct Drive Spindle with 2-steps Planetary Gearbox (Optional)

(BT-50, 6000/8000/10000rpm)

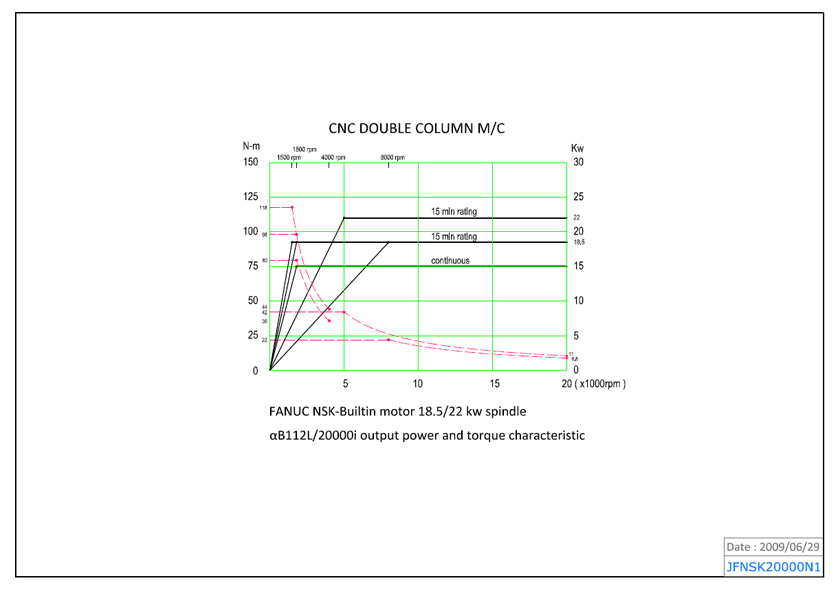

- Built-in Motor Spindle (Optional)

(BT-50 / HSK-A100, 10000rpm)

(BT-40 / HSK-A63, 18000rpm)

(HSK-A63, 12000~28000rpm inverter Spindle)

- Heads by Manual Change (Optional)

- Auto Attachment Heads Change System (Optional)

SDV-H_Metal Cutting

SDV-H_Mold Machining