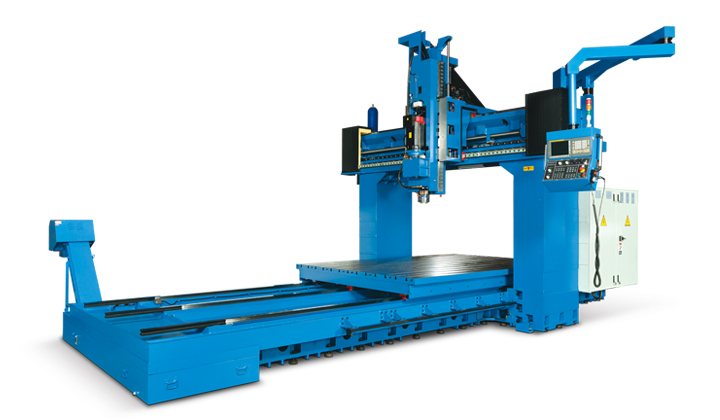

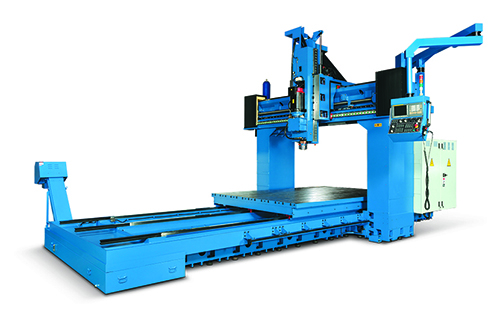

SDV series/ SDV-3224 / SDV-4224 / SDV-5224 / SDV-6224 /

CNC Double Column Machining Center

| Item / Model | Unit | SDV-3224 | SDV-4224 | SDV-5224 | SDV-6224 |

|---|---|---|---|---|---|

| X-Axis Travel | mm | 3200 | 4200 | 5200 | 6200 |

| Y-Axis Travel | mm | 2400 | 2900 | 2400 | 2400 |

| Z-Axis Travel | mm | 760 ( 1000 ) | |||

| Table Size | mm | 3000 x 2200 | 4000 x 2700 | 5000 x 2200 | 6000 x 2200 |

| T-Slots Dimension | mm | 22 ( 24、28 ) | |||

| Table Load Capacity | kgs | 10000 | 17000 | 17500 | 25000 |

| Distance between Twe Columns | mm | 2500 | 3000 | 2500 | 2500 |

| Distance from Spindle Nose to Table | mm | 250 ~ 1010 ( 250 ~ 1250 ) 145 ~ 905 ( 145 ~ 1145 ) |

|||

| Spindle Taper, Tool Shank | ISO NO.50(40) BT-50、CAT-50、DIN 69871 (BT-40、CAT-40) | ||||

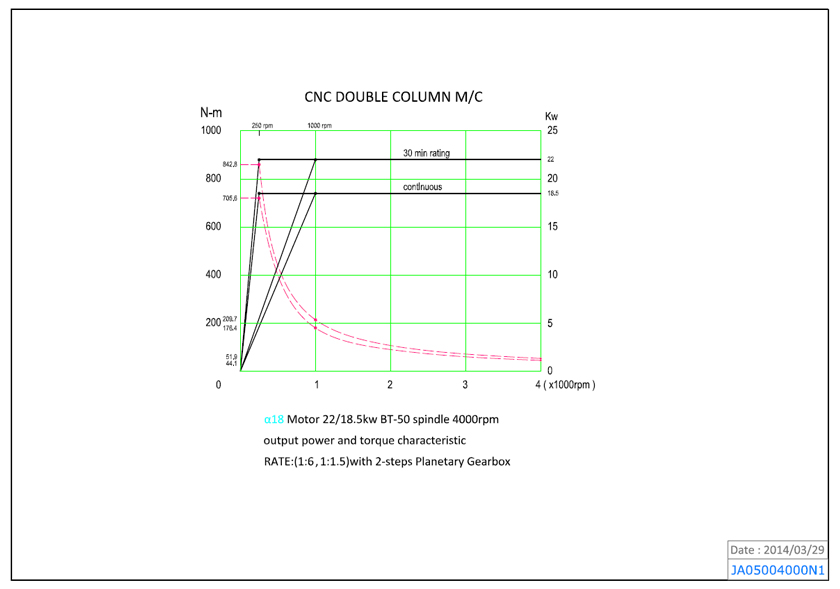

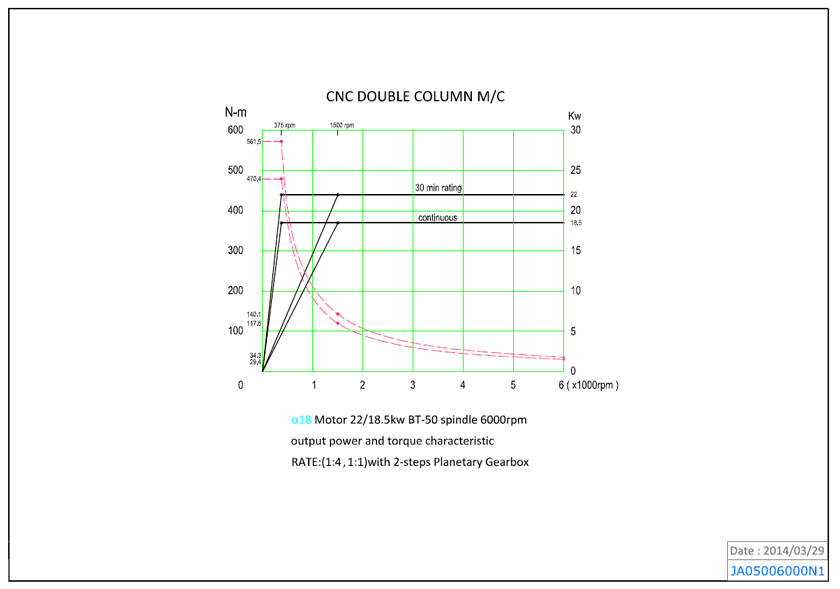

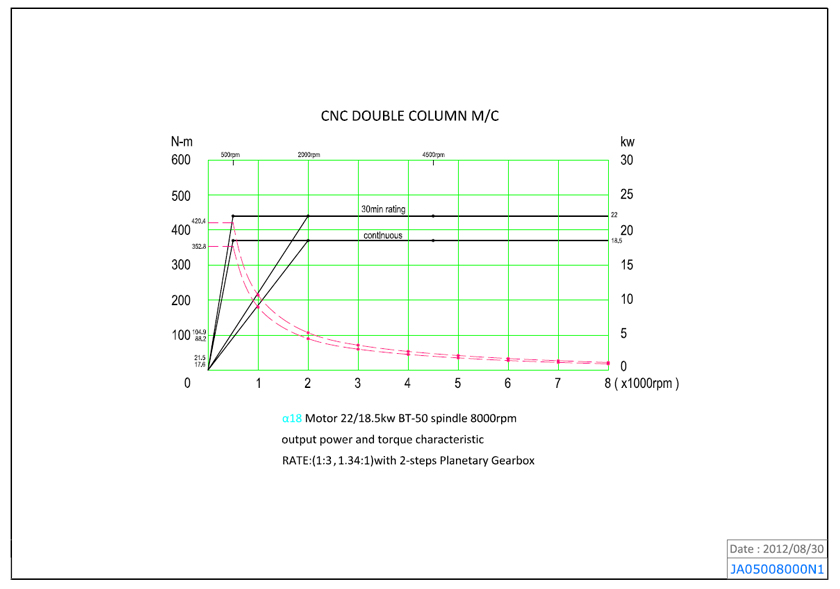

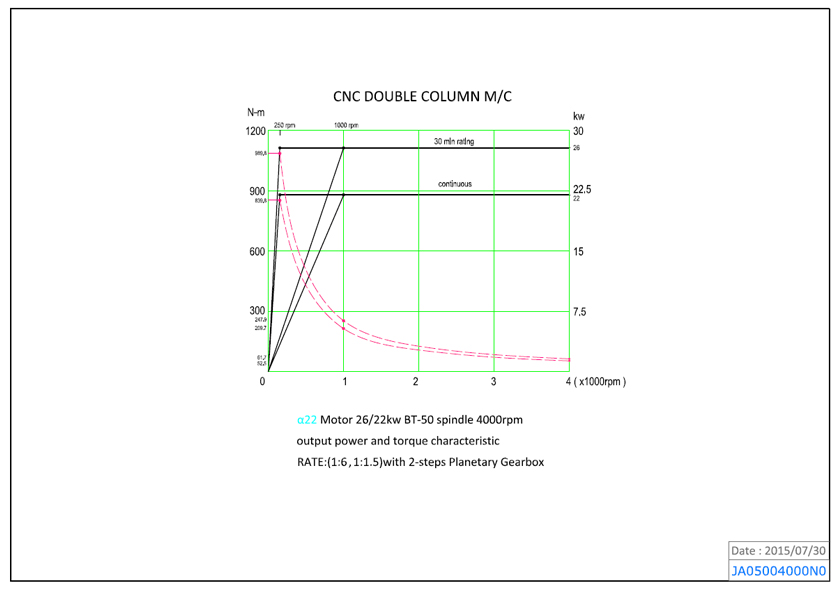

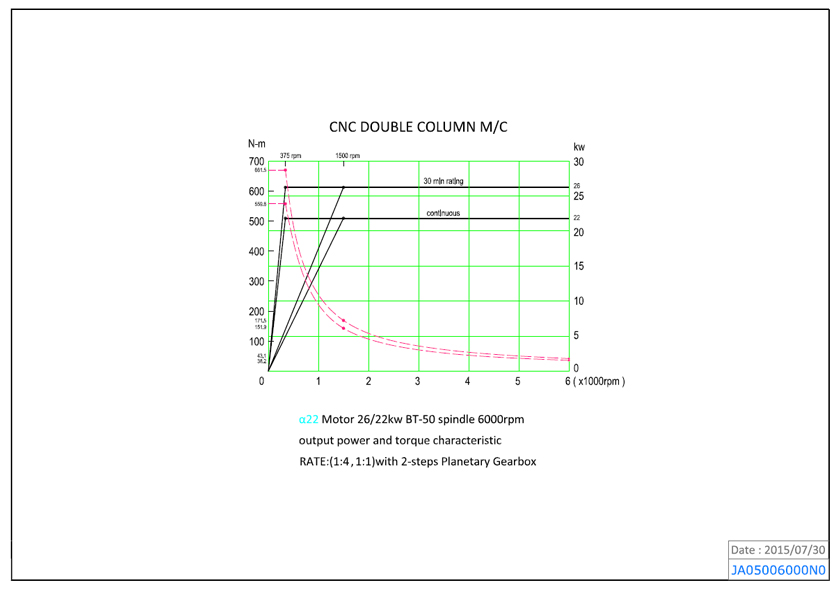

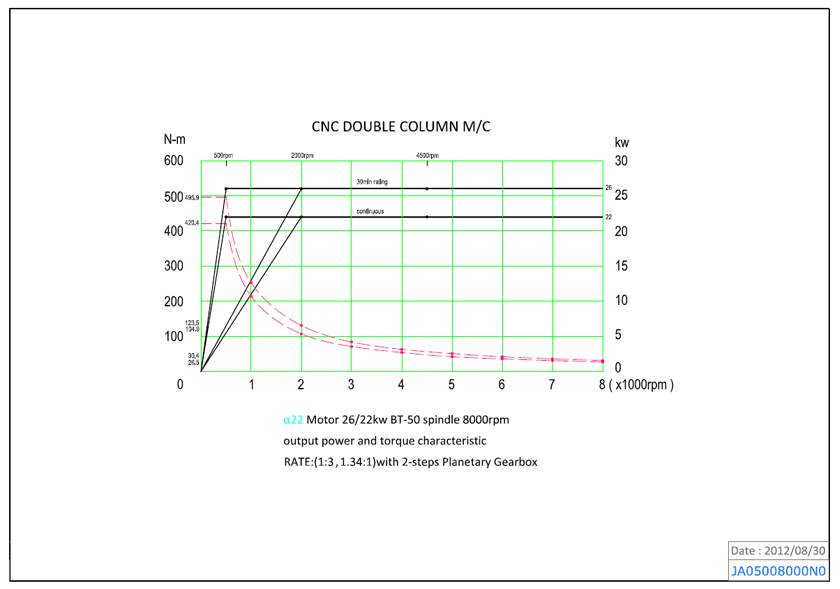

| Spindle Speed Range | rpm | 20 ~ 4000 ( 30 ~ 6000 ) ( 100 ~ 10000 ) ( 80 ~ 8000 ) | |||

| Main Motor Output (30 min Rating/Cont) |

HP | 25 / 20 ( 30 / 25 ) ( 35 / 30 ) | |||

| Rapid Traverse Rate X,Y Axis | mm/min | 10000 ( 12000 ) | |||

| Rapid Traverse Rate Z Axis | mm/min | 12000 ( 15000 ) | |||

| Cutting Feed Rate | mm/min | 1 ~ 5000 ( 1 ~ 8000 ) | |||

| Minimum Input Increment | mm/min | 0.001 | |||

| Tool Magazine Capacity | pcs | ( 16 / 20 / 32 / 40 / 60 ) | |||

| Max. Tool Diameter / Adjacent Pockets Empty |

mm | Ø125 / Ø 210 | |||

| Max. Tool Length (from Gauge Line) |

mm | 350 | |||

| Max. Tool Weight | kgs | (18 / 20) | |||

| Tool selection Method | (ABS, Random Bi) | ||||

| Tool Change Time(T-T)(approx) | secs | 8 (4.5) | |||

| Power Requirement | Kva | 45 ( 50 ) | 50 ( 55 ) | 55 ( 60 ) | |

| Floor Space Requirement | mm | 10700x7000 | 13000x7000 | 15000x7000 | 17300x7000 |

| Machine Height from Floor Level | mm | 4240 / 4760 | |||

| Machine Weight(approx) | kgs | 32500 | 37000 | 55000 | 69000 |

| CNC Controller | Fanuc, Meldas, Siemens, Heldenhain Series etc. |

||||

| Positioning Accuracry | mm | JIS B6338 0.01/300 , VDI 3441 P0.025 | JIS B6338 0.01/300 , VDI 3441 P0.035 | ||

| Repeatability Accuracy | mm | ±0.005 | |||

Note:

- ( ) Description is optional accessories.

- To research and improve our company keep the right of changing design and structure at any time, this data is just for reference.

- LUBRICATION SYSTEM

- GLAZED WINDOW-TYPE SPLASH GUARD

- SCREW-TYPE CHIP CONVEYOR

- LINK-TYPE CHIP CONVEYOR

- COOLANT EQUIPMENT

- SPINDLE OIL COOLER

- Z-AXIS HYDRAULIC BALANCE UNIT

- PNEUMATIC UNIT

- AIR BLOW FOR CHIP ( BY M-CODE )

- WORK LAMP

- AUTO POWER-OFF

- M.P.G

- PROGRAM END&ALARM LAMP

- RS-232 INTERFACE

- LEVELING BLOCK AND BOLTS

- TOOL KIT

- MAINTENANCE AND OPERATION MANUAL

- INSPECTION LIST

- AUXILIARY TABLE

- NC(ROTARY TABLE,INDEX TABLE)

- 16、20、32、40、60、ATC MAGAZINE CAPACITY

- TOOL PRESETTER

- AUTO TOOL LENGTH DIAMETER MEASUREMENT

- AUTO TOUCH PROBE SYSYTEM

- LINEAR SCALE FEEDBACK

- COOLANT THROUGH SPINDLE SYSTEM

- OIL HOLE TOOL SHANK DEVICE

- COOLANT AUTO AIR MIST DEVICE

- COOLANT NOZZLE ANGLE REMOTE CONTROL

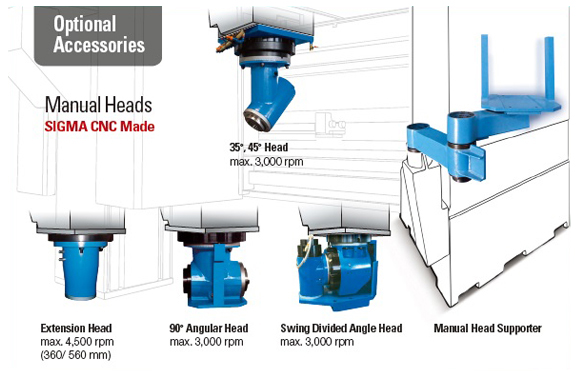

- MANUAL 45° , 90° ANGLE HEAD、UNIVERSAL HEAD 、EXTENSION HEAD MANUAL SET-UP AUTO DEVIDED 5° POSITION (RIGHT ANGLE HEAD, SWING DEVIDED ANGLE HEAD, 45° ANGLE HEAD)

- SPINDLE THERMAL COMPENSATION

- AVALIABLE WITH DIFFERENT SPINDLE SPEC & RPM

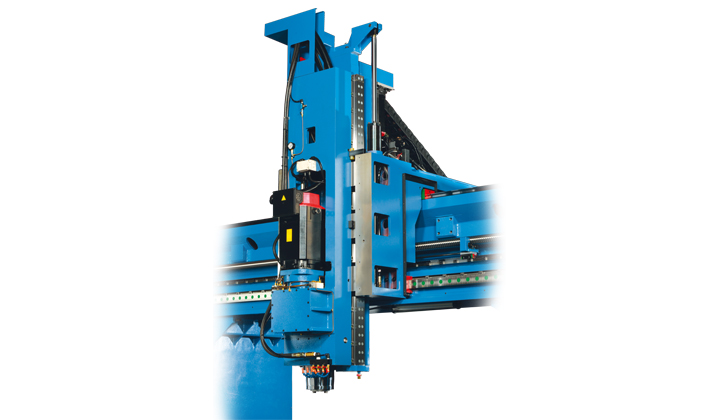

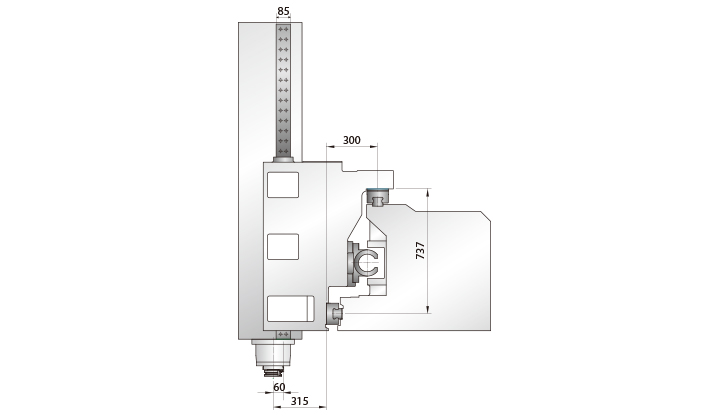

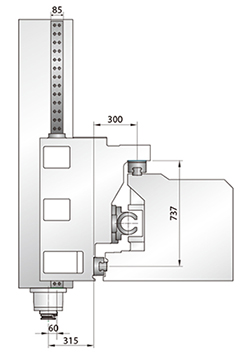

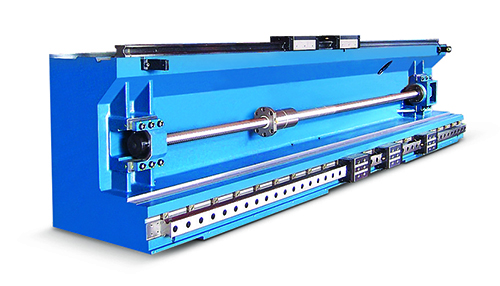

- The Ram motion of Z-axis is supported by 2 Linear Guideways.

Z-axis linear guideways width 85mm. THK-SRW series.

Spindle center to Z-axis linear guideways distance only 60mm.

- Y-axis linear guideways are configured for horizontal and vertical directions.

- All three axes(X, Y, Z) are Roller type linear guideways.

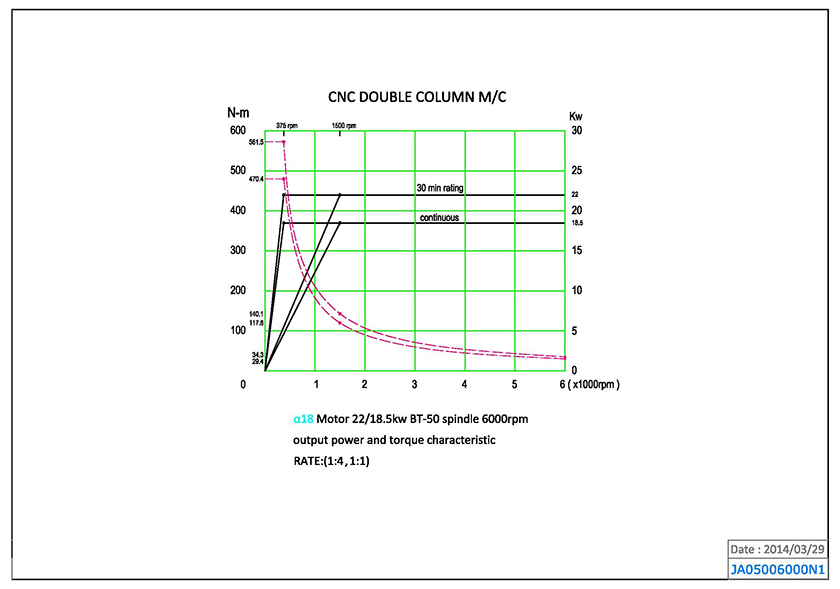

- Gears Drive Spindle (Standard).

SIGMA CNC – Self-made 2-steps Gearbox.

BT-50, Max. 6000rpm.

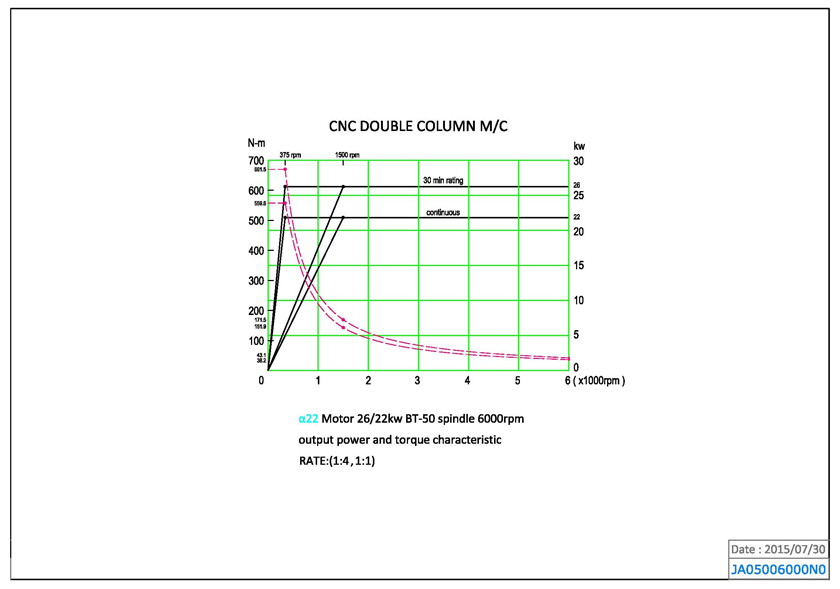

- Belt Drive Spindle (Optional).

With 2-steps Planetary Gearbox.

BT-50, Max. 4000rpm / 6000rpm /8000 rpm.

- Heads by Manual Change (Optional).

SDV_Heavy Cutting