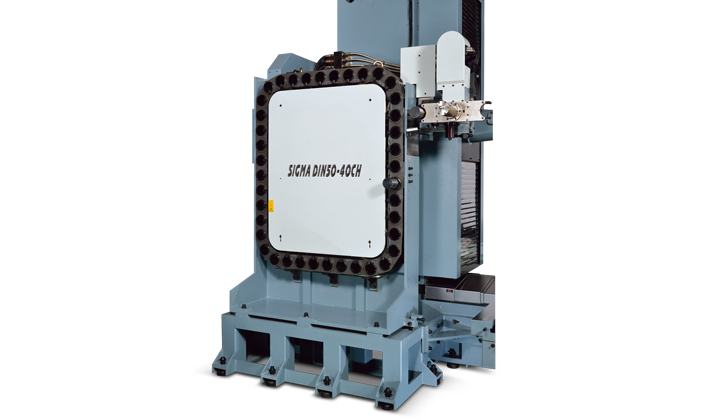

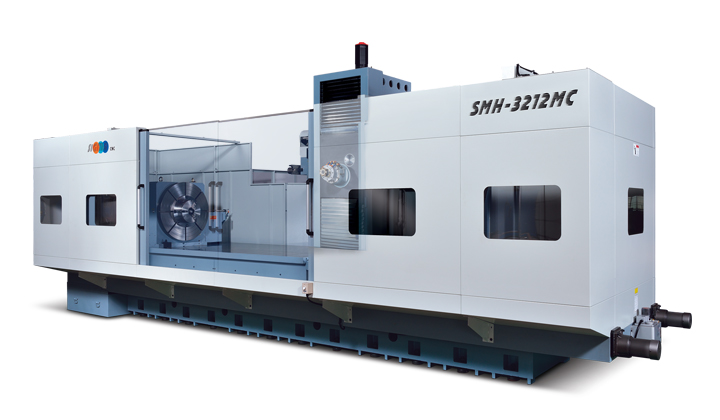

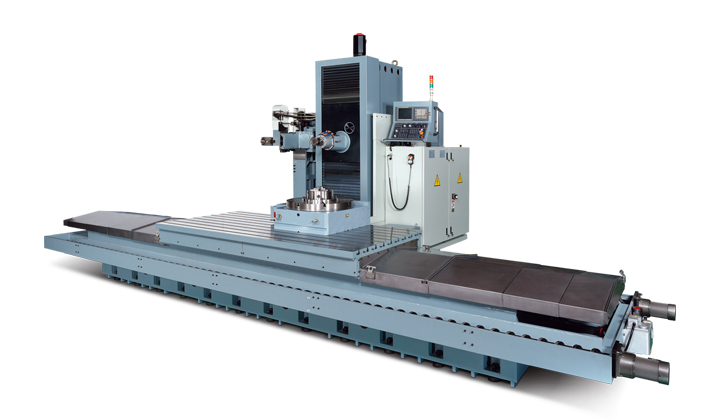

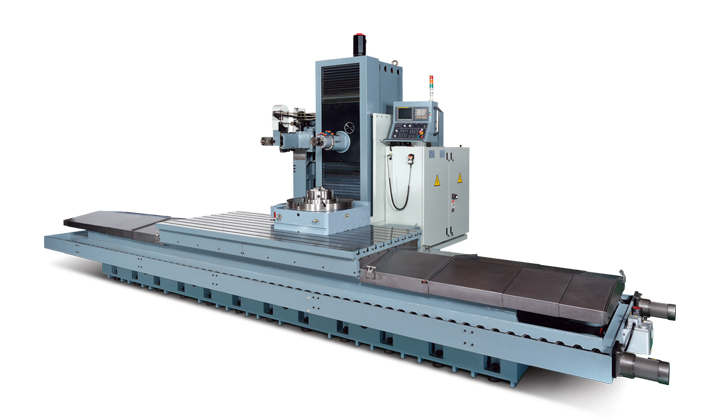

SMH series/ SMH-1608MC / SMH-2010MC / SMH-3212MC /

CNC High Speed Moving Column Horizontal Machining Center

| Item | Description | Unit | SMH-1608MC | SMH-2010MC | SMH-3212MC |

|---|---|---|---|---|---|

| Table | Size | mm | 1600 x 1000 | 2000 x 1000 | 3000 x 1400 |

| T-slots (W×No.) | mm | 22 x 7 | 22 x 9 | ||

| Top to ground height | mm | 850 | |||

| Max. loading capacity | Kgs | 3000 | 3500 | 7000 | |

| Travel | X-axis | mm | 1600 | 2040 | 3200 |

| Y-axis | mm | 800 | 1000 | 1200 | |

| Z-axis | mm | 950 ( 1200 ) | |||

| Table center to spindle nose | mm | 135 ~ 1085 | 135 ~ 1085 | 235 ~ 1185 | |

| Table top to spindle center | mm | 400 ~ 1200 | 300 ~ 1300 | 300 ~ 1500 | |

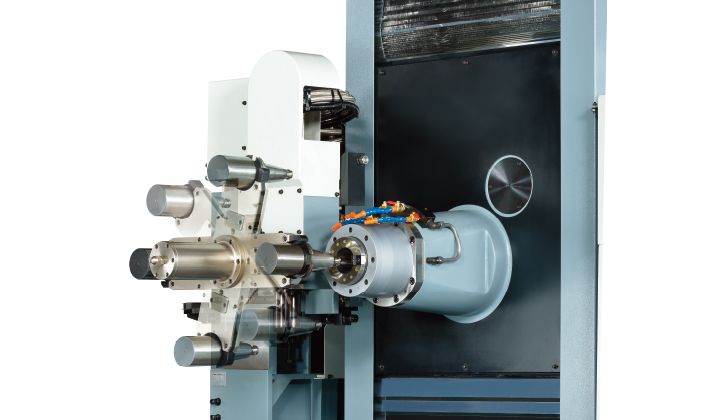

| Spindle | Taper | ISO NO50 | |||

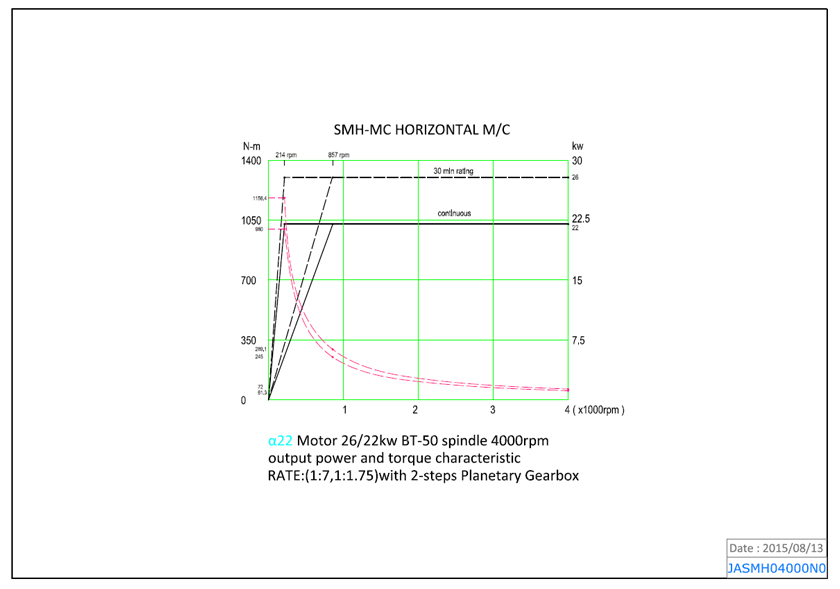

| Speed | rpm | 20 ~ 4000 ( 30 ~ 6000 ) | |||

| Feed | Rapid speed (X.Y.Z) | mm/min | 15000 | ||

| Cutting Feed | mm/min | 1 ~ 5000 ( 8000 ) | |||

| Min. input increment | mm | 0.001 | |||

| Detector of Servo | PULSE CODER ( LINEAR SCALE ) | ||||

| ATC | Tools magazine capacity | Pcs | 40 ( 60、80、120 ) | ||

| Tool shank taper | BT-50 | ||||

| Tool selection method | RANDOM BI (ABS) | ||||

| Max. tool diameter/adjacent pockets empty | mm | Ø 125 ( Ø 250 ) | |||

| Max. tool length | mm | 400 | |||

| Max. tool weight | Kgs | 25 | |||

| Tool change time (T-T) | Secs | 8 | |||

| Drive Motor | Spindle | HP | 30 / 35 | ||

| X-axis | HP | 5.4 | 9.3 | 9.3 | |

| Y-axis | HP | 5.4 | 5.4 | 5.4 | |

| Z-axis | HP | 5.4 | 5.4 | 5.4 | |

| Hydraulic unit | HP | 5 | |||

| Spindle oil cooler | HP | 1 | |||

| Lubrication unit | W | 25 | |||

| Chip conveyor | HP | ¼ | |||

| Coolant system | HP | 1 | |||

| Else | Hydraulic tank capacity | L | 120 | ||

| Oil cooler tank capacity | L | 30 | |||

| Coolant tank capacity | L | 400 | 450 | 500 | |

| Lubrication tank capacity | L | 6 | 6 | 8 | |

| Dimension of machine | mm | 5200x5000x3300 | 6200x5000x3600 | 8800x5000x4000 | |

| Machine weight (approx) (Included A.T.C. Magazine) |

Kgs | 17500 | 21000 | 25000 | |

| CNC CONTROLLER | FANUC、MITSUBISHI、SIEMENS、Heidenhain | ||||

Note:

- ( ) Description is optional accessories.

- To research and improve our company keep the right of changing design and structure at any time, this data is just for reference.

- SPINDLE COOLER SYSTEM

- HYDRAULIC SYSTEM

- COOLANT TANK UNIT

- CENTRALIZED LUBRICATION SYSTEM

- A.T.C MAGAZINE CAPACITY:40PCS

- SCREW TYPE、CHAIN TYPE CHIP CONVEYOR

- LEVELING BLOCKS & BOLTS

- TOOL KIT

- AUTO-POWER OFF SYSTEM

- PROGRAM END & ALARM LAMP

- WORK LAMP

- M.P.G

- RS232 INTERFACE

- MAIN TENANCE & OPERATION MANUAL

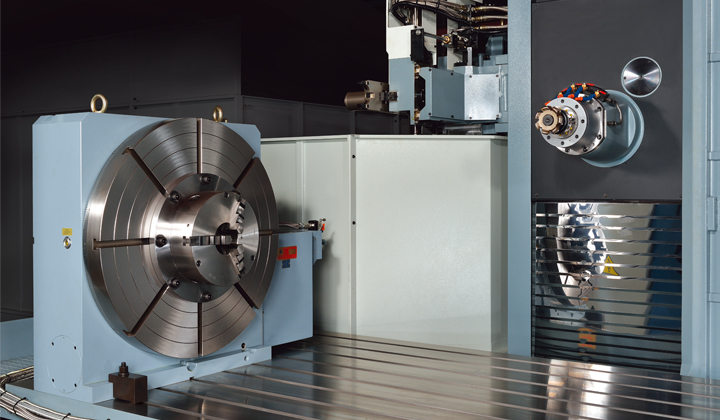

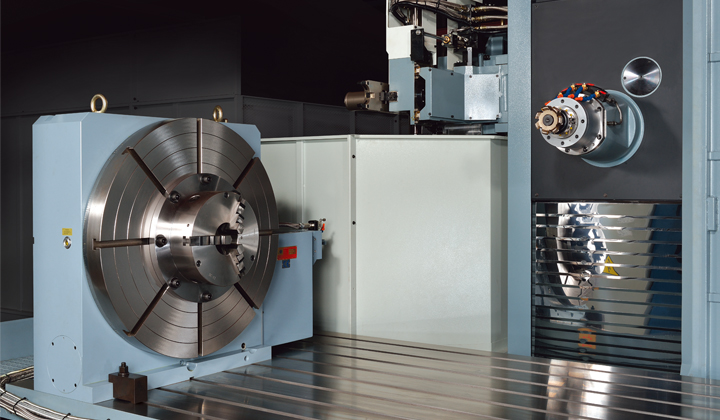

- 4th or 5th CNC ROTARY TABLE

- A.T.C MAGAZINE CAPACITY ( 60、80、120)

- COOLANT THROUGH SPINDLE SYSTEM ( 20kg/cm2 )

- COOLANT THROUGH TOOL SHANK( max 6 kg/cm2 )

- VERTICAL SQUARE WORK TABLE( 600×600×900mm )

- AUXILIARY WORK TABLE ( 900×900×100mm )

- VERTICAL SQUARE CLAMPING CUBE BP080312 (630×350×700 mm) BP090312 (630×350×700 mm)

- AUTO TOOL LENGTH DIAMETER MEASUREMENT ( RENISHAW TS-27R )、( NC4 NON-CONTACT)

- AUTO TOUCH PROBE SYSTEM( RENISHAW OMP-60 )

- TOOL PRESTTER

- COOLANT TEMPERATURE CONTROL

- DIFFERENT TYPE、FUNCTION CNC CONTROL

- AXIS LINEAR SCALE FEEDBACK

- High Loading Roller Type Linear Guideways for Three Axes

- 4th & 5th Rotary Table (Optional)

By Customer Request

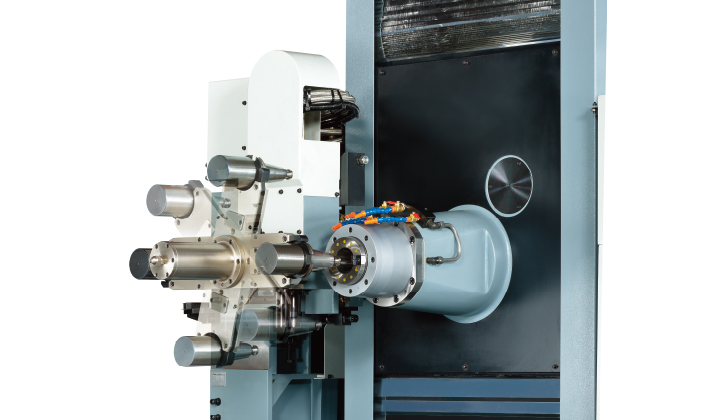

- Belt Drive type Spinlde

BT-50, 4000rpm

- Auto Tool Changer

40pcs (Optional 60 / 80 / 120pcs)

T-T Tool Change 8 sec only.