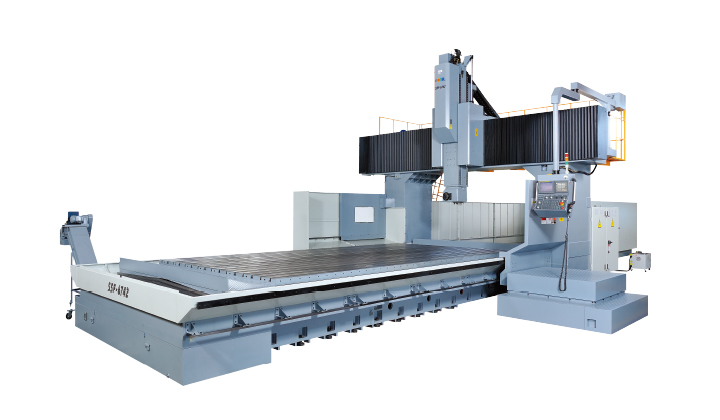

SIGMA CNC Patent - The spindle ram and Z-axis are designed with 4-linear guideways.

(Roller type guideway, width 45mm) and a box-way construction. During heavy cutting vibrations are eliminated, and during fine cutting inert does not occur, resulting in higher surface accuracy.

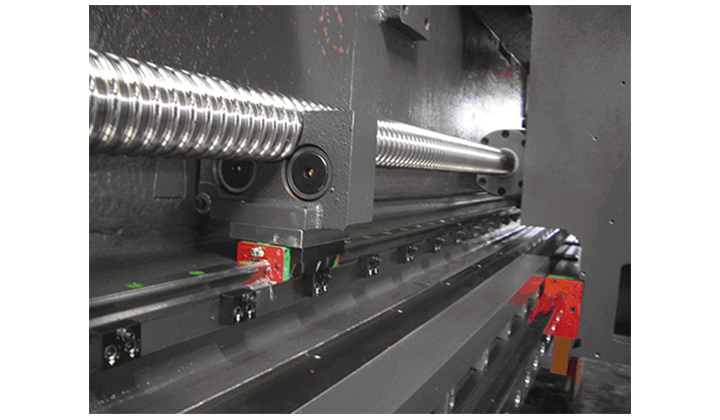

SIGMA CNC Patent – Y-axis configured by 3-linear guideways.

(Roller type guideway, width 65mm) for horizontal and vertical directions that offer greater stability and rigidity for the machine.

All three axes(X, Y, Z) are Roller type linear guideways.

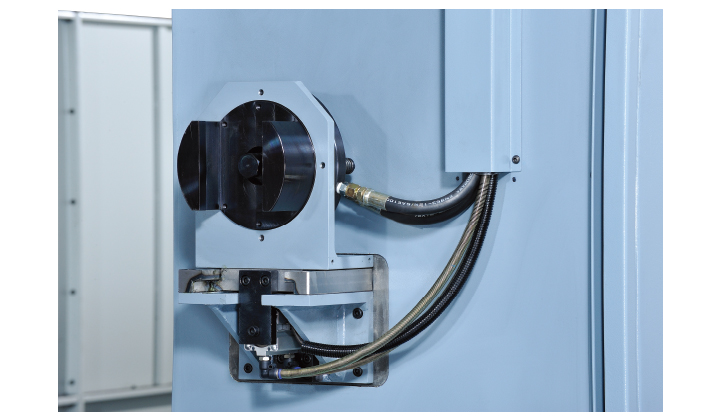

SIGMA CNC made 5-Face Head (Vertical & Horizontal, All in one)

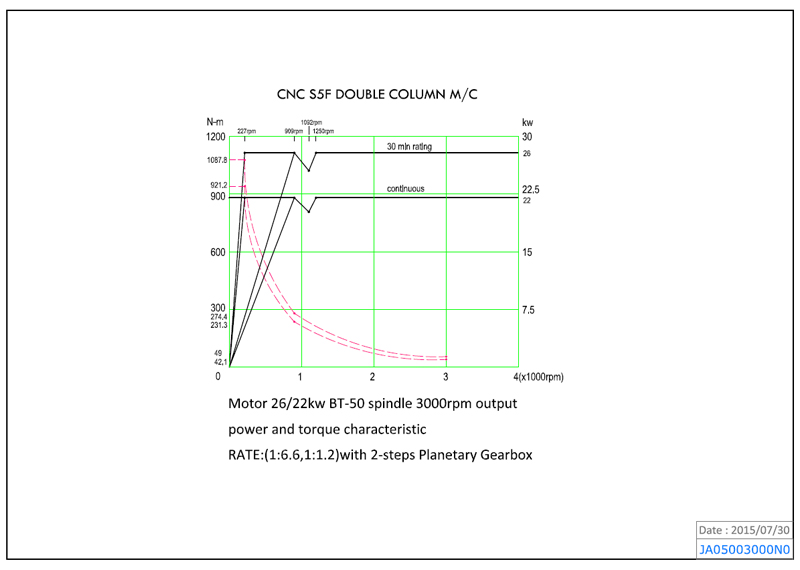

Belt Drive Type with 2-steps Planetary Gearbox

BT-50, 3000rpm

BT-50, 3000rpm

Torgue Chart

Tool Change Mechanism for Horizontal Spindle

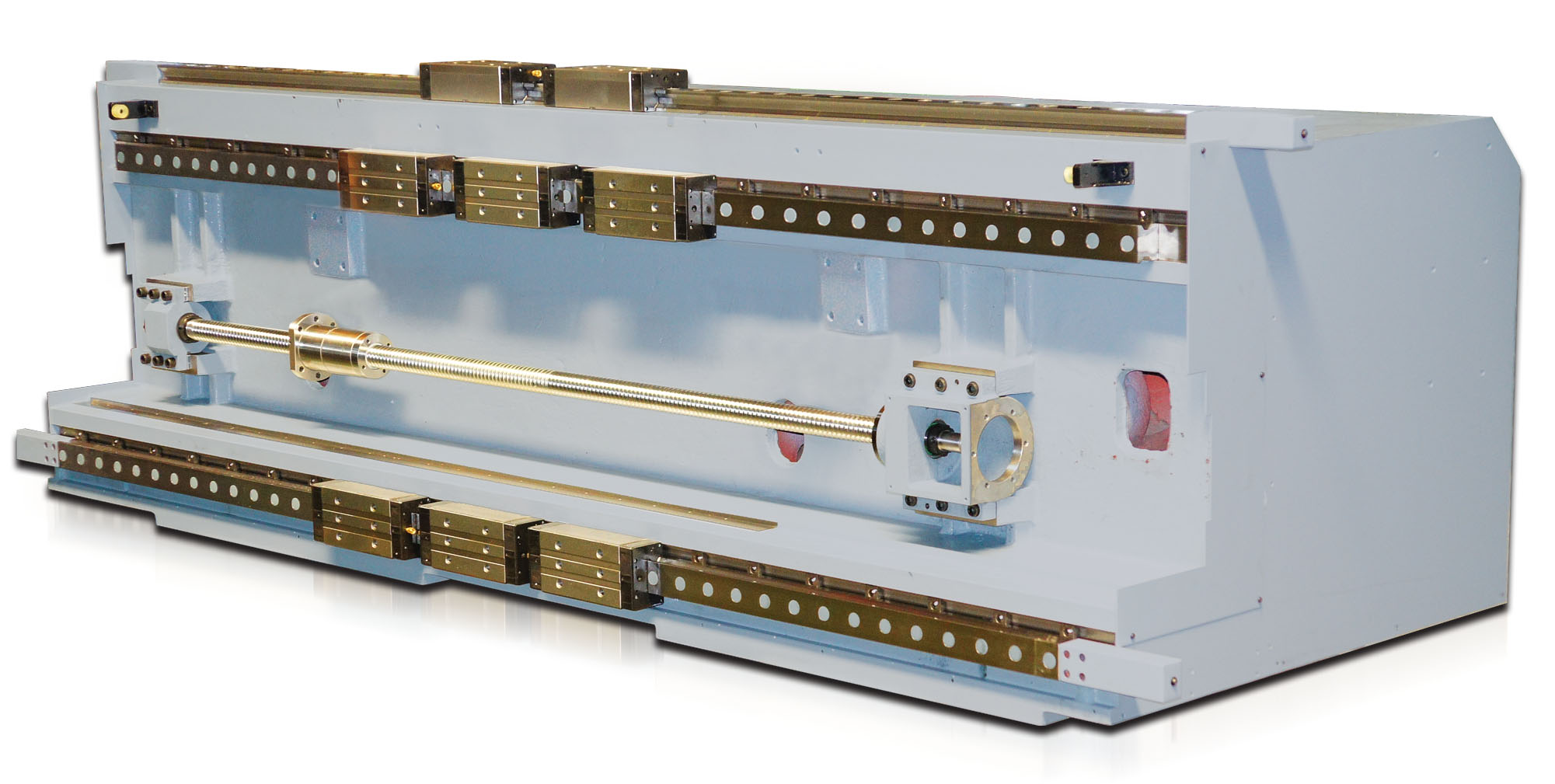

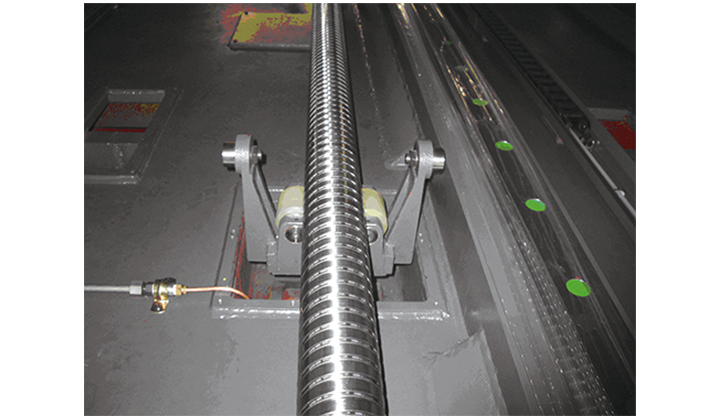

Supporter for Ballscrew on X-axis

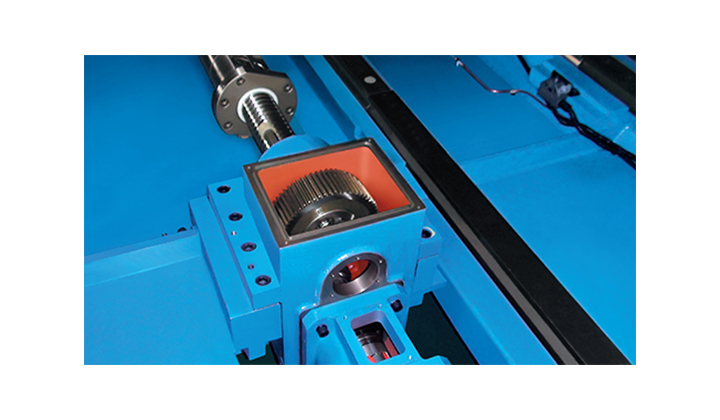

X-axis Free Backlash Transmission Gearbox

Supporter for Ballscrew on Y-axis

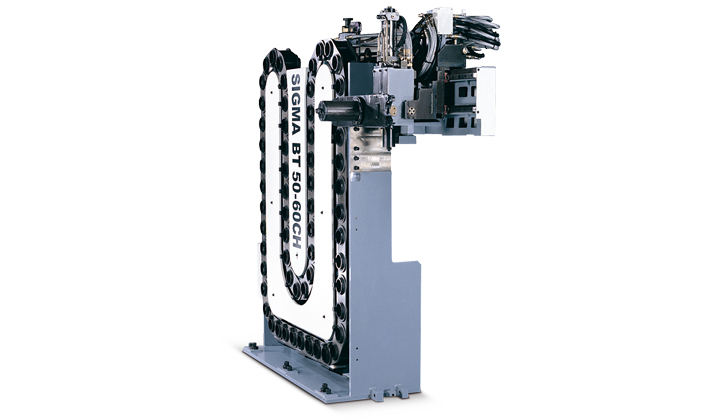

V & H Auto Tool Changer 40 pcs (Standard)

BT-50 (Optional 60 / 80 / 120pcs)