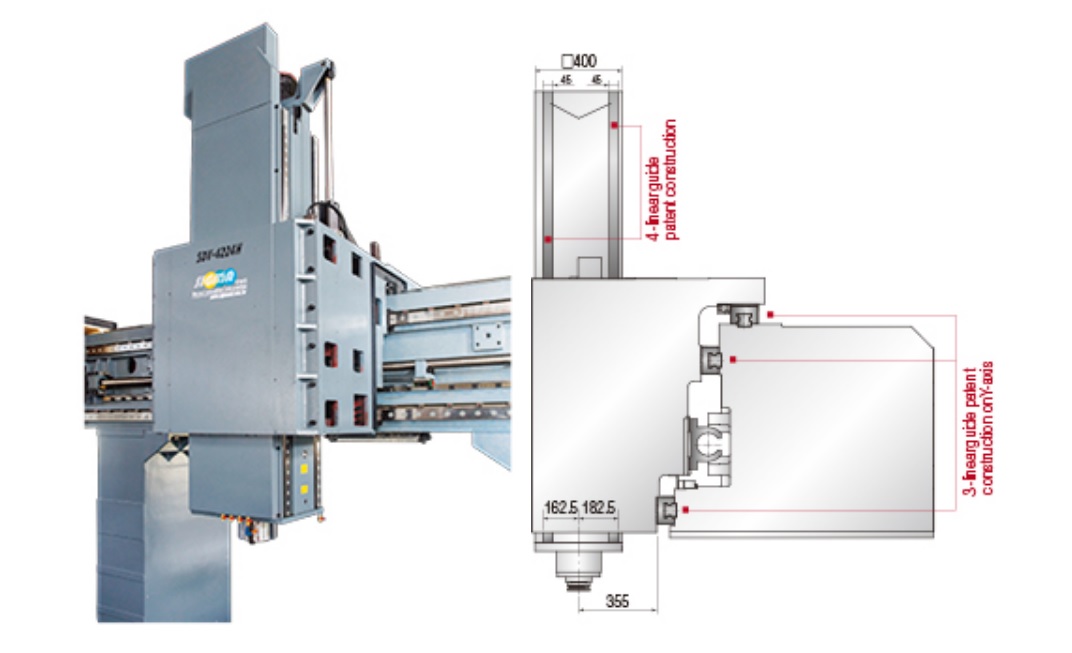

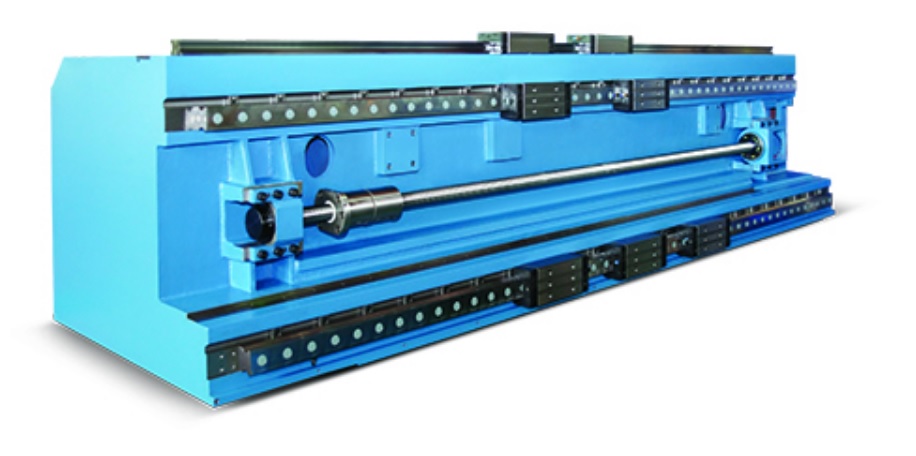

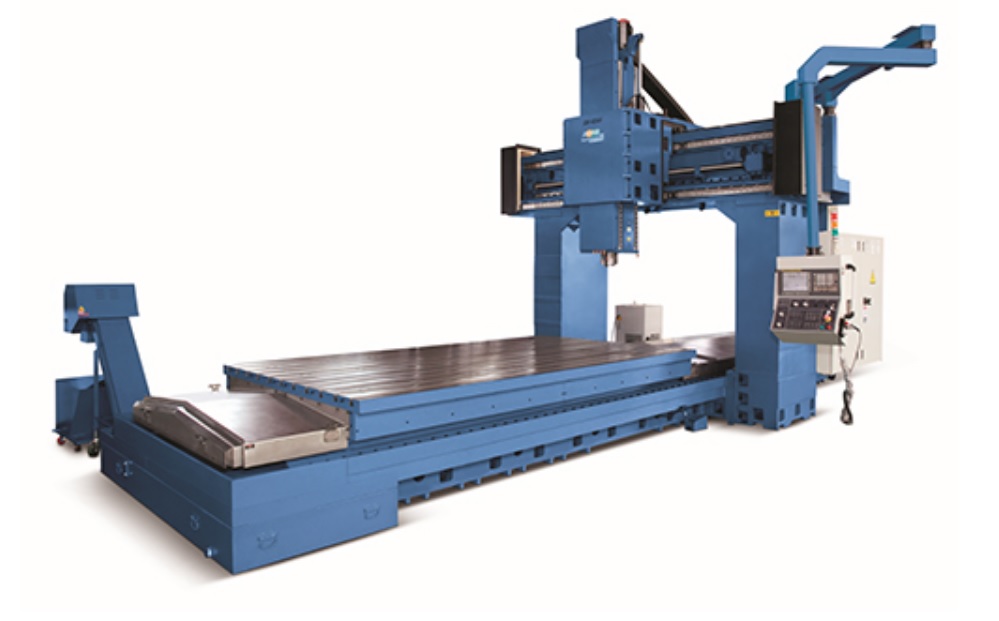

SIGMA CNC Patent - The spindle ram and Z-axis are designed with 4-linear guideways (Roller type guideway, width 45mm) and a box-way construction.

During heavy cutting vibrations are eliminated, and during fine cutting inert does not occur, resulting in higher surface accuracy.

SIGMA CNC Patent – Y-axis configured by 3-linear guideways (Roller type guideway, width 65mm)

or horizontal and vertical directions that offer greater stability and rigidity for the machine.

All three axes(X, Y, Z) are Roller type linear guideways.

Belt Drive Spindle With 2-steps Planetary Gearbox.

BT-50, Max. 4000rpm / (6000rpm) / (8000 rpm). (Opt.)

Direct Drive Spindle (Optional)

BT-50, 10000rpm

Direct Drive Spindle with 2-steps Planetary Gearbox (Optional)

BT-50, 6000/8000/10000rpm

Built-in Motor Spindle (Optional)

(BT-50 / HSK-A100, 10000rpm)

(BT-40 / HSK-A63, 18000rpm)

(HSK-A63, 12000~28000rpm inverter Spindle)

(BT-40 / HSK-A63, 18000rpm)

(HSK-A63, 12000~28000rpm inverter Spindle)

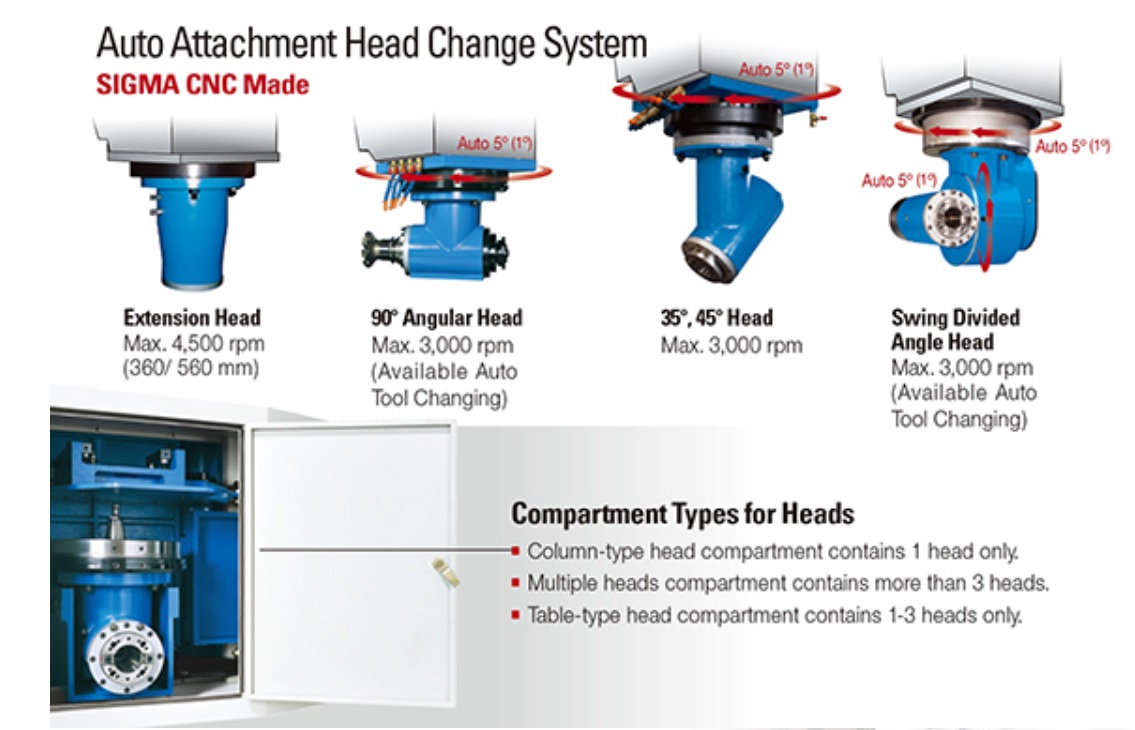

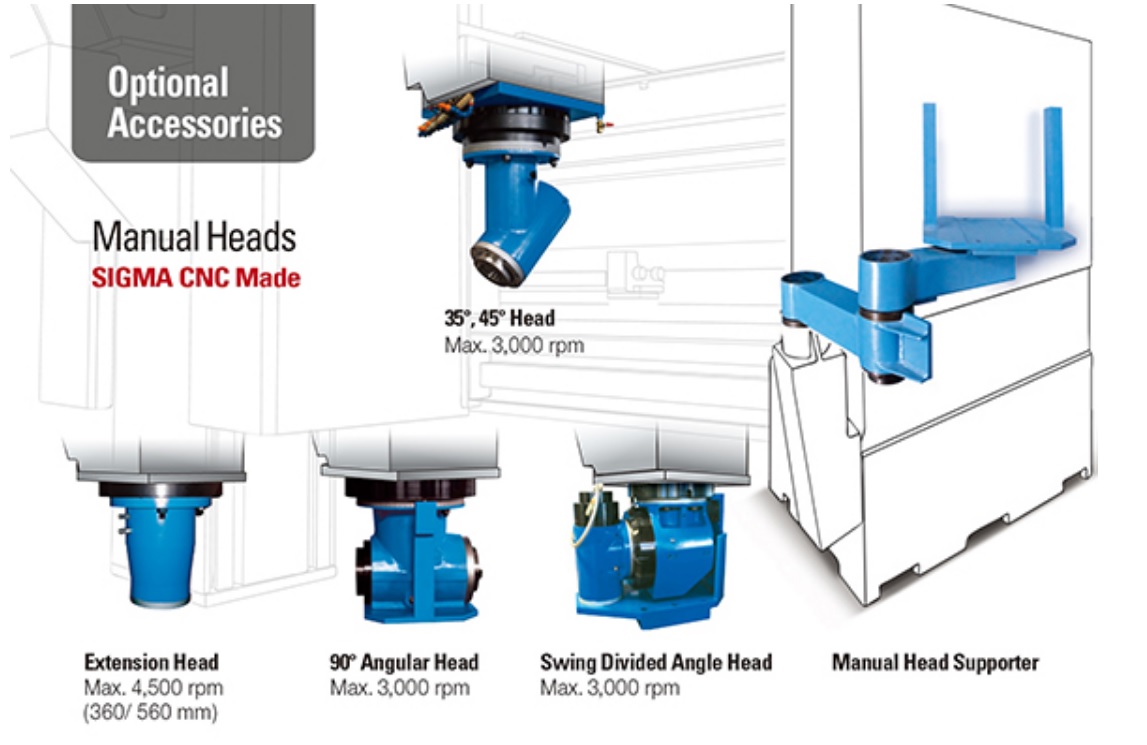

Heads by Manual Change (Optional)

Auto Attachment Heads Change System (Optional)