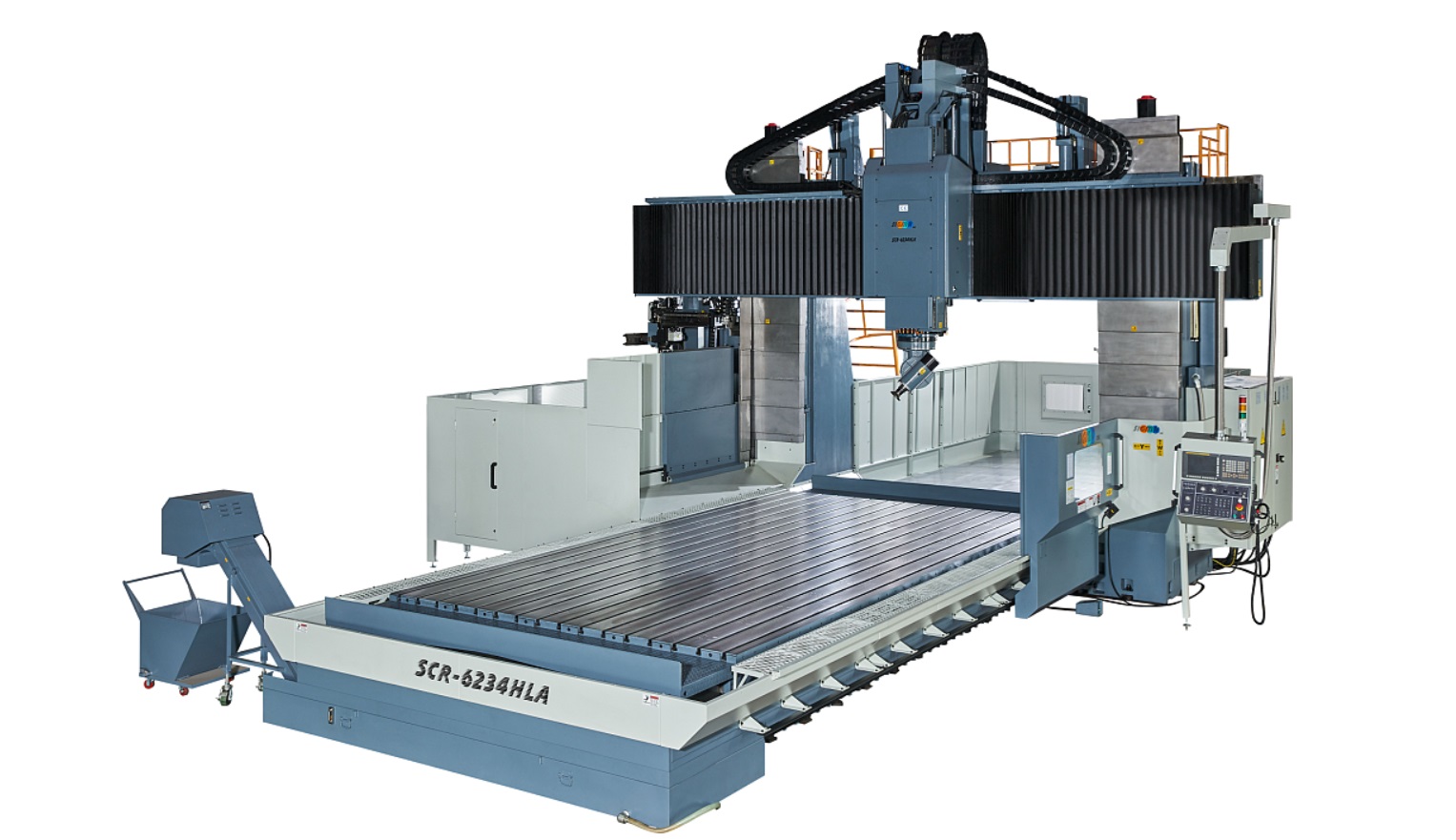

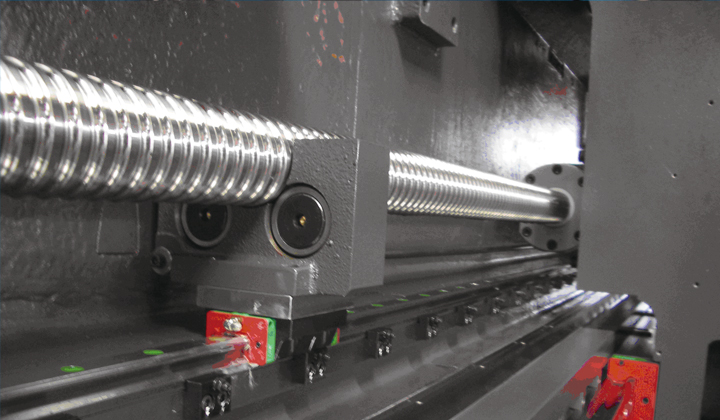

SIGMA CNC Patent - The spindle ram and Z-axis are designed with 4-linear guideways.

(Roller type guideway, width 45mm) and a box-way construction. During heavy cutting vibrations are eliminated, and during fine cutting inert does not occur, resulting in higher surface accuracy.

All three axes(X, Y, Z) are Roller type linear guideways.

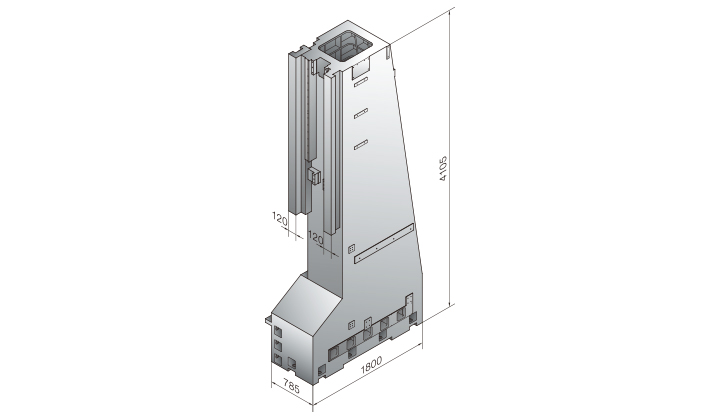

Stronger W-axis (box-way) with Super Column Design

W-axis Standard Stroke 1400mm. (It is possible to be custom-made)

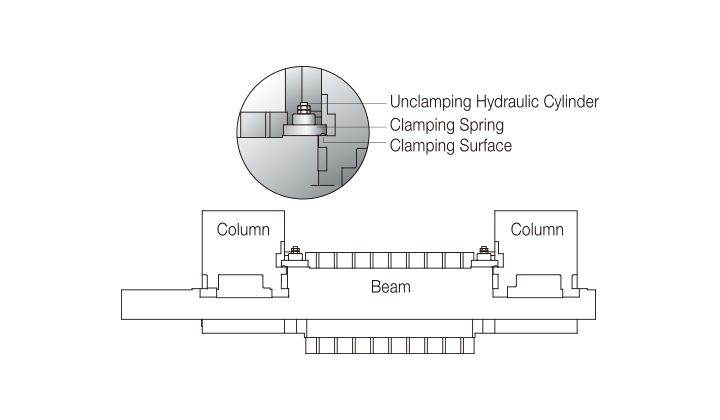

Powerful Clamping Mechanism for W-axis

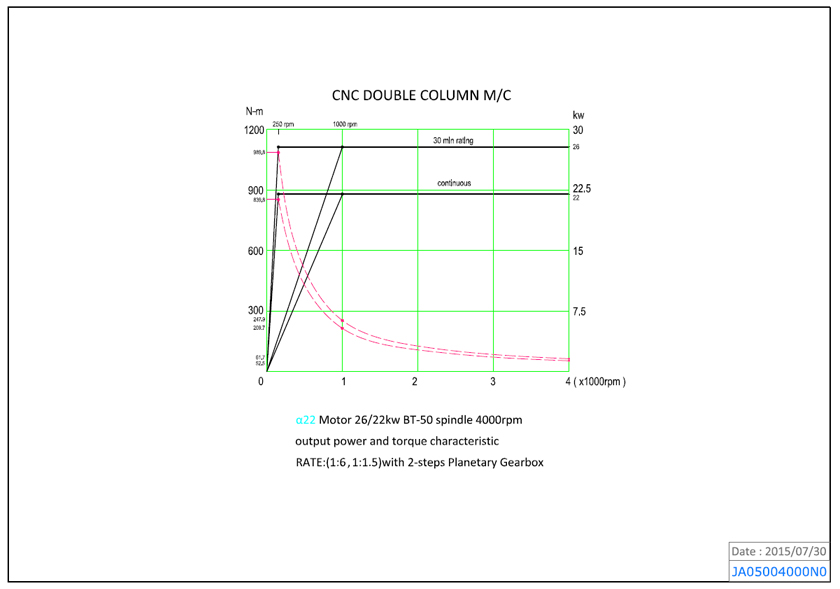

Belt Drive Spindle

With 2-steps Planetary Gearbox

BT-50, Max. 4000rpm

BT-50, Max. 4000rpm

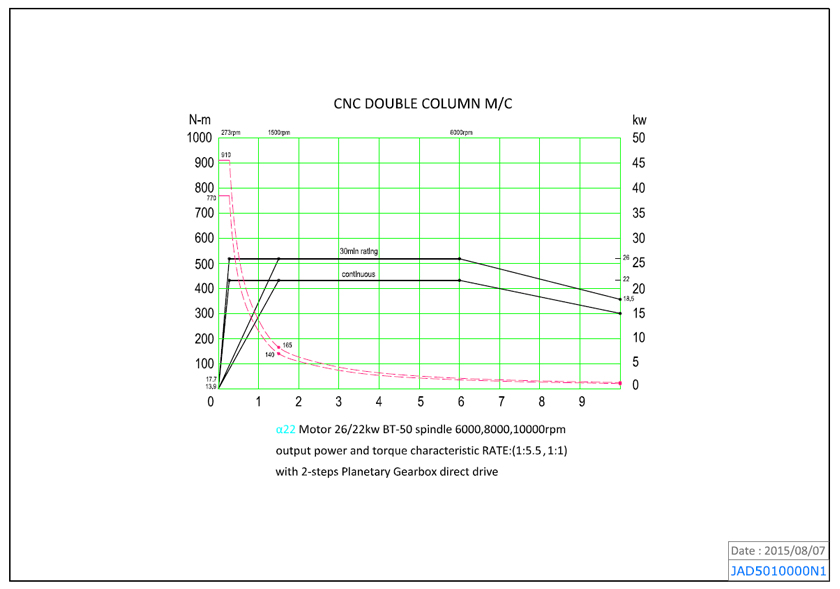

Direct-Drive Spindle with 2-steps Planetary Gearbox (Optional)

BT-50, 6000rpm / 8000rpm / 10000rpm

High Speed & High Torque in One Machine

High Speed & High Torque in One Machine

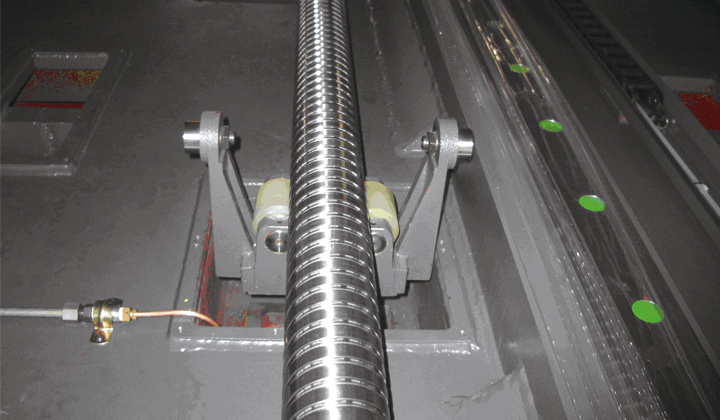

Supporter for Ballscrew on X-axis

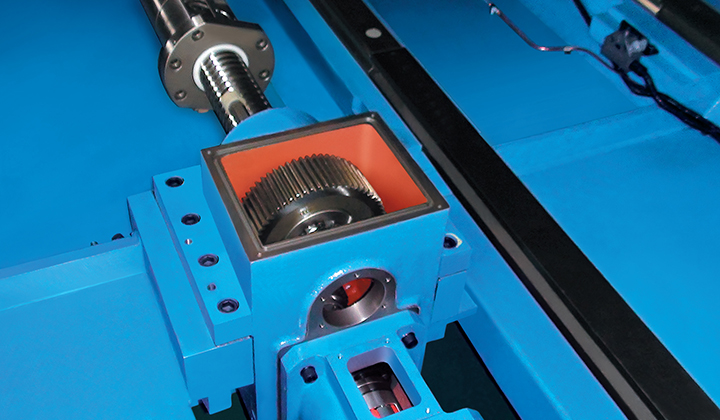

X-axis Free Backlash Transmission Gearbox

Supporter for Ballscrew on Y-axis

Operator’s Box by Lift Mechanism special for large machinery only.

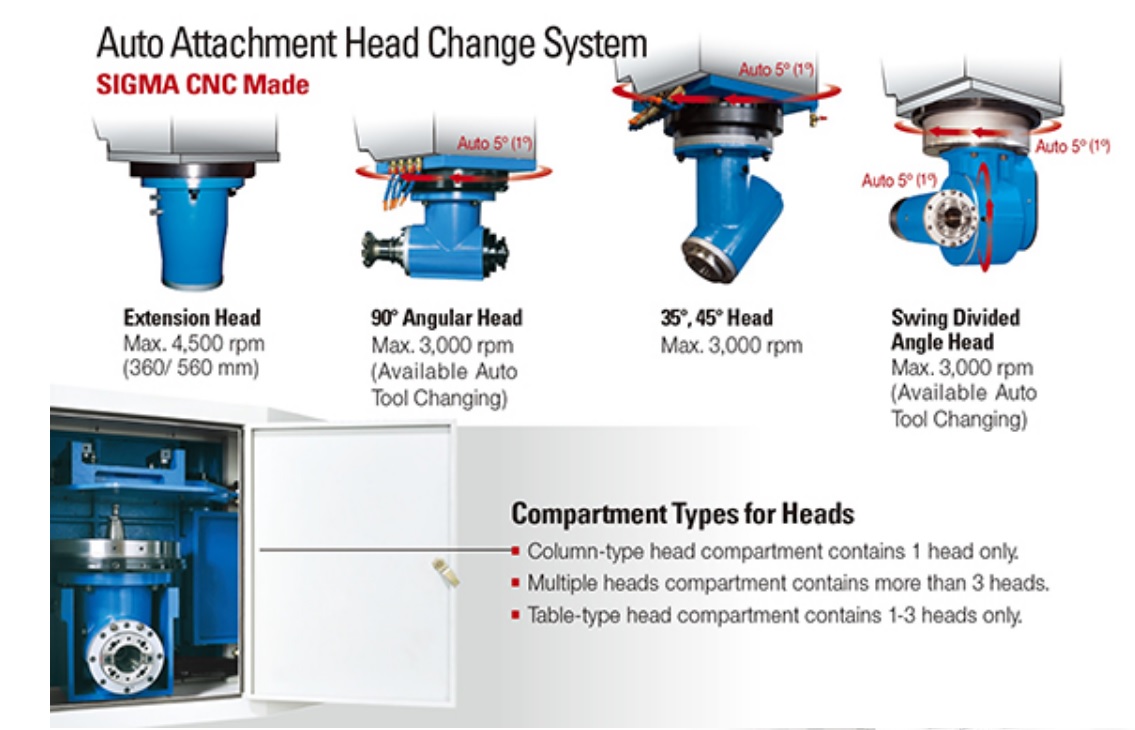

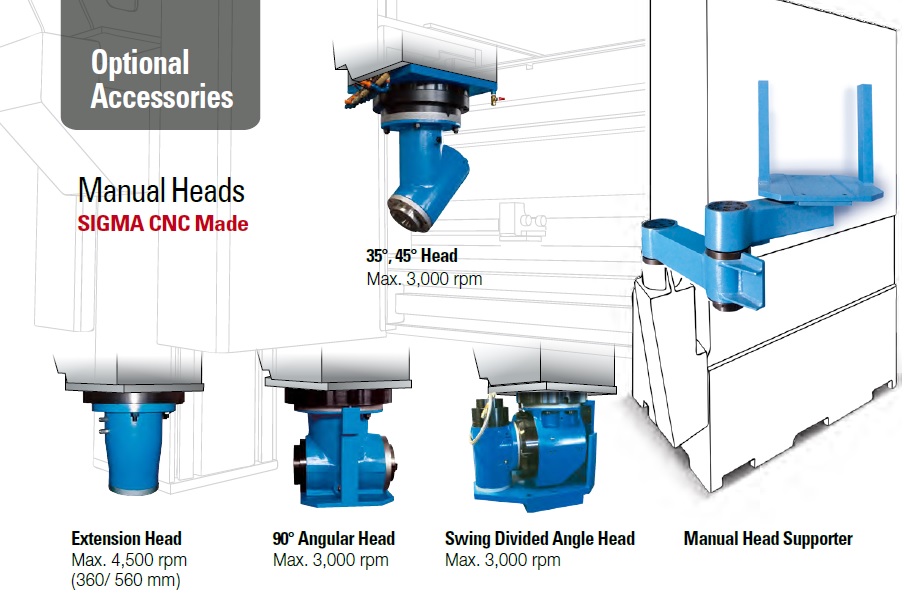

Heads by Manual Change (Optional)

Auto Attachment Heads Change System (Optional)